Quick Details

| Material: | Inconel 625, etc | Technics: | Forged | Type: | Inconel 625 Orifice Flange |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

|

|

Packaging & Delivery

| Packaging Details: | plywood case or fumigation woodern case |

|---|

| Delivery Detail: | 2 - 10 days |

|---|

Specifications

Inconel 625 Orifice Flange

1.Size: ½" to 48"

2.Class / Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, etc

3.Standard: ASME, JIS, DIN, ANSI, etc.

4.Material: Inconel 625, etc

Description Of Inconel 625 Orifice Flange

Type | Inconel 625 Orifice Flange |

Size | 1/2" To 48" (DN15-1200) |

Wall thickness |

sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, etc

|

Standards | ASME, ASTM, DIN, JIS, etc |

Material | Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc

|

Surface treatment | Transparent oil, rust-proof black oil or hot galvanized |

Applications | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

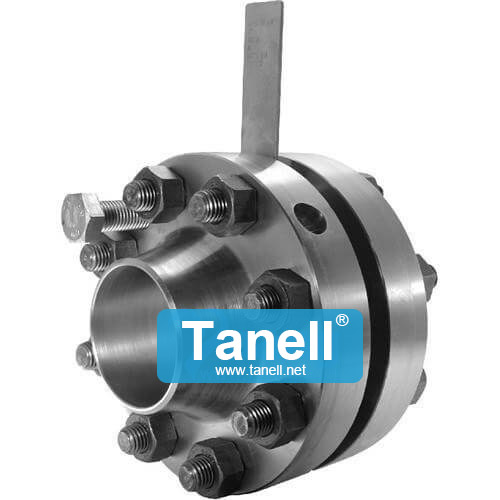

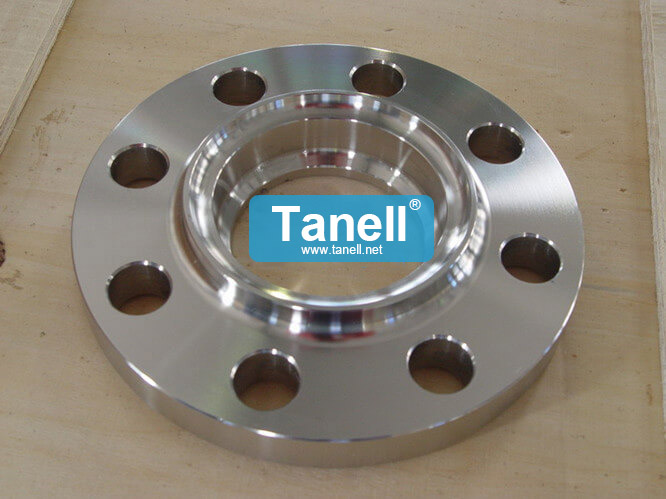

Inconel 625 Orifice Flange is used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Inconel 625 Orifice Flanges generally come with either raised faces or RTJ (Ring Type Joint) facings. They are, for all intensive purposes, the same as weld neck and slip-on flanges with extra machining. They have modifications of radial tapped holes in the flange ring for meter connections and orifice plate carriers for the reason of fitting meter connections. The additional bolts act as a jack to allow the separation of the two flanges to change the orifice plate or for other inspection services.

Inconel 625 Orifice Flange is used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Inconel 625 Orifice Flanges generally come with either raised faces or RTJ (Ring Type Joint) facings. They are, for all intensive purposes, the same as weld neck and slip-on flanges with extra machining. They have modifications of radial tapped holes in the flange ring for meter connections and orifice plate carriers for the reason of fitting meter connections. The additional bolts act as a jack to allow the separation of the two flanges to change the orifice plate or for other inspection services.

Standard | Inconel 625 |

UNS | N06625 |

Werkstoff Nr. | 2.4856 |

Chemical Composition Of Inconel 625 Orifice Flange

Weight % | Ni | Cr | Mo | Nb + Ta | Fe | Ti |

Alloy 625 | 58.0 min | 20 - 23 | 8 -10 | 3.15 -4.15 | 5.0 max | 0.40 max |

C | Mn | Si | S | P | Al | Co |

0.10 max | 0.50 max | 0.50 max | 0.15 max | 0.15 max | 0.40 max | 1.0 max |

Mechanical & Physical Properties – Inconel 625

| Density | 8.4 g/cm3 |

| Melting Point | 1350 °C (2460 °F) |

| Tensile Strength | Psi – 135,000 , MPa – 930 |

| Yield Strength (0.2%Offset) | Psi – 75,000 , MPa – 517 |

| Elongation | 42.5 % |

In what applications is Inconel 625 used?

Aircraft ducting systems

Aerospace

Jet engine exhaust systems

Engine thrust-reverser systems

Specialized seawater equipment

Chemical process equipment

Inconel 625 is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Inconel Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN.

Inconel 625 Orifice Flange's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps,

pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality Inconel 625 Orifice Flange.

You can visit this website: www.tanell.net(Zhejiang Tanell industry technology Co., Ltd.)

If any inquiry about products, please feel free to contact us tan@tanell.com

Inconel 625 Orifice Flange is used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Inconel 625 Orifice Flanges generally come with either raised faces or RTJ (Ring Type Joint) facings. They are, for all intensive purposes, the same as weld neck and slip-on flanges with extra machining. They have modifications of radial tapped holes in the flange ring for meter connections and orifice plate carriers for the reason of fitting meter connections. The additional bolts act as a jack to allow the separation of the two flanges to change the orifice plate or for other inspection services.

Inconel 625 Orifice Flange is used with orifice meters for the purpose of measuring the flow rate of either liquids or gases in the respective pipeline. Inconel 625 Orifice Flanges generally come with either raised faces or RTJ (Ring Type Joint) facings. They are, for all intensive purposes, the same as weld neck and slip-on flanges with extra machining. They have modifications of radial tapped holes in the flange ring for meter connections and orifice plate carriers for the reason of fitting meter connections. The additional bolts act as a jack to allow the separation of the two flanges to change the orifice plate or for other inspection services.