Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

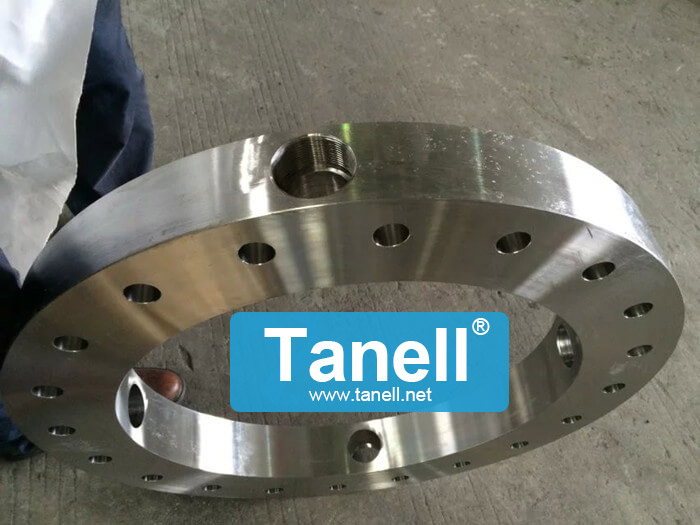

A bleed ring is a ring section with one or more radial pipe connections designed to fit between standard flanges within the bolt circle, using conventional gasket material. The ring normally comes with a 1/2 inch socket weld or 3/4 inch tapped for connecting with valves and instruments. The face of the ring can also be made to matched with any flange type, and has different sizes based on the ASME flange rating of the process piping.

Bleed Rings can provide a beneficial way of draining piping, taking samples, attaching instruments or even bleeding of a valve. They can also be used with a valve and/or blind flange, this allows you to reduce and dispose of the pressure for your valve before you remove the flange. This is usually done with a replacement for a leaky valve.

The bleed ring can come in any material or size, and is designed for connecting valves and instruments. The face of the bleed ring can be manufactured to match with any flange type. The standard sizes for a bleed ring are NPS 1 to NPS 24 and ASME Pressure Classes 150 through 1500. It comes in many different materials such as carbon steel, stainless steel etc.

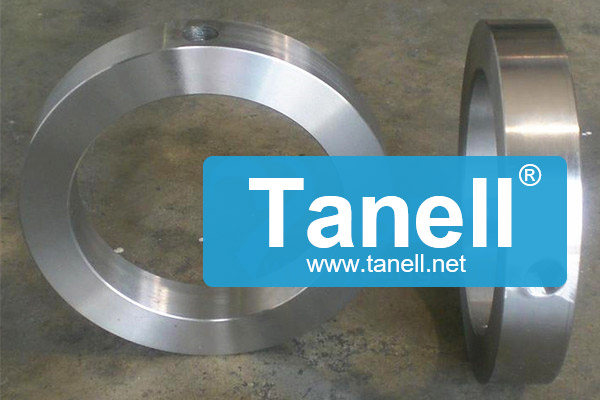

Drip Rings, or Flushing Rings, are used in the oil or gas line. They are coupled between two seals.

The Drip Ring is circular, as a ring, with one or two holes. They may have one or two branches, based the usage that is made for.

In the branch’s hole can be inserted instruments: pressure gauge, thermowell or it can be free to allow the drainage of condensate.

In correspondence to each hole the Drip Ring can be welded to a Weldoflange or a branch connector.

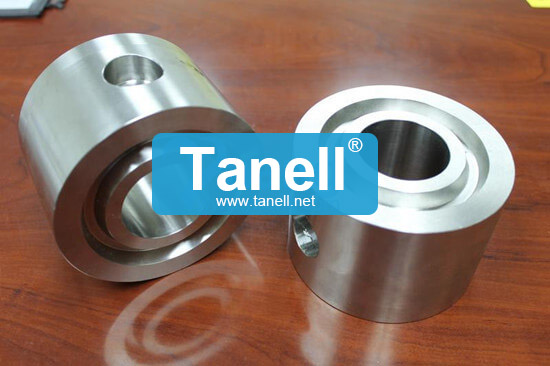

The flushing rings are used for flushing solution combined with diaphragm seals. This type of flushing flange or ring is clamped between process nozzle and diaphragm seal. The reducer flange is used to mount a larger diaphragm seal to a smaller process connection. This type of reducer flange is clamped between process nozzle and diaphragm seal.

Diaphragm Seal Accessories are carefully designed to optimise the use of the Diaphragm Seal in your process conditions, or to ease the installation and protect it against damaging during installation.

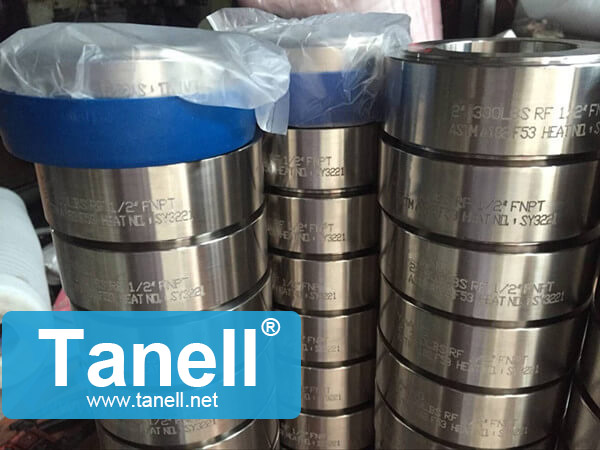

Tanell manufacures Bleed & Flush Rings, Drip Ring from 1/2' to 24' in different types of materials as follow:

Carbon steel (ASTM 105, A516 Gr. 60/65/70, A350 LF2, A694 F60-65)

Stainless steel (AISI 304, 316, 321, 347)

Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22)

Nickel alloys

Duplex/Super duplex (F51, F53, F55, F44)

Incoloy (800, 800H, 800 HT, 825), Alloy 20

Hastelloy (C22, C276)

Cupronickel Cu-Ni

Monel 400

Inconel (600, 625)

Titanium (Gr. 1, 2, 3)

Tanell manufactures Drip Ring RJ and FF-RF (Class 150/300/600/900/1500/2500) with one hole 3/4' NPT or two holes 1/2' NPT in according to standard TB.DRI 5011 and in according to special customer's requirements.

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.569 Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.