Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

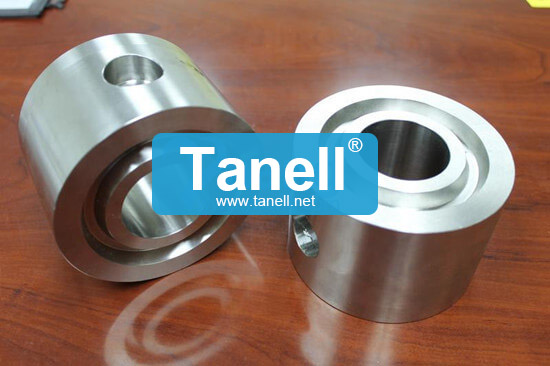

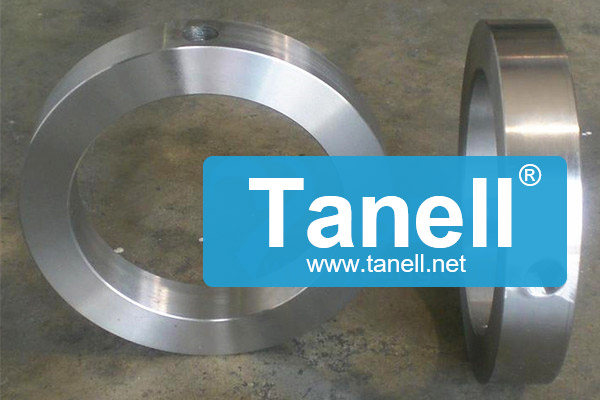

ASME B16.5 ASTM A182 316L Bleed Ring

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Quick Details

| Material: | 316L | Technics: | Forged | Type: | Bleed Ring |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

Packaging & Delivery

| Packaging Details: | plywood case or fumigation woodern case |

|---|---|

| Delivery Detail: | 2 - 10 days |

Specifications

ASME B16.5 ASTM A182 316L Bleed Ring

1. Material: ASTM A182 316L 2. Size: 1/2" - 24" (DN15 - DN600) 3. Standard: ASME B16.5

4. Pressure: 150#, 300#, 600#, 900#, 1500#, etc

A bleed ring is a ring section with one or more radial pipe connections designed to fit between standard flanges within the bolt circle, using conventional gasket material. The ring normally comes with a 3/4" tapped or 1/2" socket weld for connecting with valves and instruments. The face of the ring can also be made to matched with any flange type. A bleed ring has different sizes based on the ANSI flange rating of the process piping.

A bleed ring can be used instead of an Orifice Flange union. It is easier to install and cheaper than installing orifice flanges, especially in a brown field application. It comes in many different materials such as carbon steel, stainless steel, alloy st, ect., depending on the use. They provide a convenient way of draining piping, taking samples, attaching instruments or even bleeding of a valve. When used with a valve and Blind Flange, it allows you to relieve the pressure if your valve is leaking before you remove the flange.

China Bleed Ring Manufacturer Tanell offers ASME B16.5 ASTM A182 316L Bleed Ring.

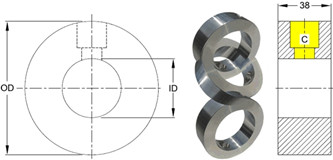

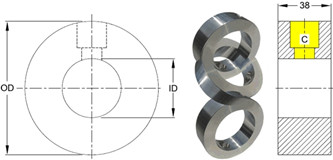

Dimensions of Bleed Rings according to ASME 31.3, B16.5, B16.20, NPS 1 to NPS 12

NPS ID PRESSURE CLASS 150 300 600 900 1500 1 28.6 63.5 69.9 69.9 76.2 76.2 1½ 41.3 82.6 92.1 92.1 95.3 95.3 2 54 101.6 108 108 139.7 139.7 2½ 63.5 120.7 127 127 161.9 161.9 3 79.4 133.4 146.1 146.1 165.1 171.5 4 104.8 171.5 177.8 190.5 203.2 206.4 6 155.6 219.1 247.7 263.5 285.8 279.4 8 203.2 276.2 304.8 317.5 355.6 349.3 10 257.2 336.6 358.8 396.9 431.8 431.8 12 304.8 406.4 419.1 450.9 492.1 514.4

Notes:

Dimensions are in millimeters unless otherwise indicated.

C - 1/2 inch or 3/4 inch threaded or socket weld taps are standard. Multiple taps can be provided but must be orientated by customer. Thickness of ring may be affected if larger taps are required.

X - Depending on the inside diameter of pipe or fitting.

Standard finish of gasket surface shall be machined to 125-250 Serrated finish. Other surface finish must be specified by customer.

4. Pressure: 150#, 300#, 600#, 900#, 1500#, etc

A bleed ring is a ring section with one or more radial pipe connections designed to fit between standard flanges within the bolt circle, using conventional gasket material. The ring normally comes with a 3/4" tapped or 1/2" socket weld for connecting with valves and instruments. The face of the ring can also be made to matched with any flange type. A bleed ring has different sizes based on the ANSI flange rating of the process piping.

A bleed ring can be used instead of an Orifice Flange union. It is easier to install and cheaper than installing orifice flanges, especially in a brown field application. It comes in many different materials such as carbon steel, stainless steel, alloy st, ect., depending on the use. They provide a convenient way of draining piping, taking samples, attaching instruments or even bleeding of a valve. When used with a valve and Blind Flange, it allows you to relieve the pressure if your valve is leaking before you remove the flange.

China Bleed Ring Manufacturer Tanell offers ASME B16.5 ASTM A182 316L Bleed Ring.

Dimensions of Bleed Rings according to ASME 31.3, B16.5, B16.20, NPS 1 to NPS 12

| NPS | ID | PRESSURE CLASS | ||||

| 150 | 300 | 600 | 900 | 1500 | ||

| 1 | 28.6 | 63.5 | 69.9 | 69.9 | 76.2 | 76.2 |

| 1½ | 41.3 | 82.6 | 92.1 | 92.1 | 95.3 | 95.3 |

| 2 | 54 | 101.6 | 108 | 108 | 139.7 | 139.7 |

| 2½ | 63.5 | 120.7 | 127 | 127 | 161.9 | 161.9 |

| 3 | 79.4 | 133.4 | 146.1 | 146.1 | 165.1 | 171.5 |

| 4 | 104.8 | 171.5 | 177.8 | 190.5 | 203.2 | 206.4 |

| 6 | 155.6 | 219.1 | 247.7 | 263.5 | 285.8 | 279.4 |

| 8 | 203.2 | 276.2 | 304.8 | 317.5 | 355.6 | 349.3 |

| 10 | 257.2 | 336.6 | 358.8 | 396.9 | 431.8 | 431.8 |

| 12 | 304.8 | 406.4 | 419.1 | 450.9 | 492.1 | 514.4 |

Notes:

Dimensions are in millimeters unless otherwise indicated.

C - 1/2 inch or 3/4 inch threaded or socket weld taps are standard. Multiple taps can be provided but must be orientated by customer. Thickness of ring may be affected if larger taps are required.

X - Depending on the inside diameter of pipe or fitting.

Standard finish of gasket surface shall be machined to 125-250 Serrated finish. Other surface finish must be specified by customer.

Description Of ASME B16.5 ASTM A182 316L Bleed Ring

Type

ASME B16.5 ASTM A182 316L Bleed Ring Size

1/2" - 24" (DN15 - DN600)

Standards

ASME 31.3, B16.5, B16.20, etc

Material

Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc

Stainless Steel: ASTM A182 F304/304L/316/316L, etc

Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc.

Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc

Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc

Cu-Ni: 90/10,70/30, etc

Haet treatment

Normalized / Annealed / Quenched / tempered

Applications

Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

Chemical Composition Of 316L

Chemical Composition and Mechanical Property For 316L

Steel Grade

Chemical Composition

Mechanical Performance

C(Max)

Si(Max)

Mn(Max)

P(Max)

S(Max)

Ni

Cr

Mo

N

Tensile Strength

(Min)

Yield Strength

(Min)

Mpa

Mpa

316L

0.03

0.75

2.00

0.045

0.03

10.0–14.0

16.0–18.0

2.00–3.00

0.1

485

170

Description Of ASME B16.5 ASTM A182 316L Bleed Ring

Type | ASME B16.5 ASTM A182 316L Bleed Ring |

Size | 1/2" - 24" (DN15 - DN600) |

Standards | ASME 31.3, B16.5, B16.20, etc |

Material | Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

Haet treatment | Normalized / Annealed / Quenched / tempered |

Applications | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

Chemical Composition Of 316L

Chemical Composition and Mechanical Property For 316L | |||||||||||

Steel Grade | Chemical Composition | Mechanical Performance | |||||||||

C(Max) | Si(Max) | Mn(Max) | P(Max) | S(Max) | Ni | Cr | Mo | N | Tensile Strength | Yield Strength | |

Mpa | Mpa | ||||||||||

316L | 0.03 | 0.75 | 2.00 | 0.045 | 0.03 | 10.0–14.0 | 16.0–18.0 | 2.00–3.00 | 0.1 | 485 | 170 |

Tanell manufacures Bleed Rings from 1/2" to 24" in different types of materials as follow:

Carbon steel (ASTM 105, A516 Gr. 60/65/70, A350 LF2, A694 F60-65)

Stainless steel (AISI 304, 316, 321, 347)

Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22)

Nickel alloys

Duplex/Super duplex (F51, F53, F55, F44)

Incoloy (800, 800H, 800 HT, 825), Alloy 20

Hastelloy (C22, C276)

Cupronickel Cu-Ni

Monel 400

Inconel (600, 625)

Titanium (Gr. 1, 2, 3)

Tanell manufacture Drip Ring RJ and FF-RF (Class 150/300/600/900/1500/2500) with one hole 3/4" NPT or two holes 1/2" NPT in according to standard TB.DRI 5011 and in according to special customer's requirements.

Tanell manufacures Bleed Rings from 1/2" to 24" in different types of materials as follow:

Carbon steel (ASTM 105, A516 Gr. 60/65/70, A350 LF2, A694 F60-65)

Stainless steel (AISI 304, 316, 321, 347)

Alloy steel (AISI Gr.1, Gr.5, Gr.9, Gr.91, Gr.11, Gr.22)

Nickel alloys

Duplex/Super duplex (F51, F53, F55, F44)

Incoloy (800, 800H, 800 HT, 825), Alloy 20

Hastelloy (C22, C276)

Cupronickel Cu-Ni

Monel 400

Inconel (600, 625)

Titanium (Gr. 1, 2, 3)

Tanell manufacture Drip Ring RJ and FF-RF (Class 150/300/600/900/1500/2500) with one hole 3/4" NPT or two holes 1/2" NPT in according to standard TB.DRI 5011 and in according to special customer's requirements.

ASME B16.5 ASTM A182 316L Bleed Ring's Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps,

pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request.

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.5 ASTM A182 316L Bleed Ring.

You can visit this website: tanell.net(Zhejiang Tanell Pipes&Fitting Co., Ltd)

If any inquiry about products, please feel free to contact us tan@tanell.com

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.