Quick Details

| Material: | Hastelloy C276, etc | Technics: | Forged | Type: | Alloy 20 180 Degree Elbow |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

|

|

Packaging & Delivery

| Packaging Details: | plywood case or fumigation woodern case |

|---|

| Delivery Detail: | 2 - 10 days |

|---|

Specifications

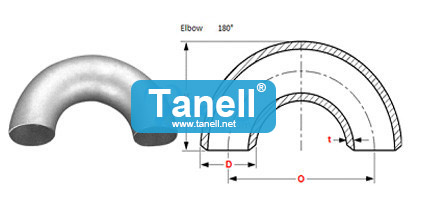

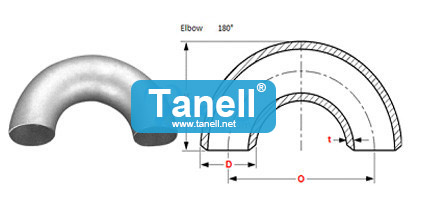

Alloy 20 180 Degree Elbow

1) Size: 1/2"~48" (DN15 - DN1200)

2) THK: SCH5S - SCH160 XXS

3) Material: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800,

Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc

Alloy 20 180 Degree Elbow is mainly used for connecting two pipes or tubes,

allowing a change of direction. We can provide short radius elbows and long radius elbows.

Usually, 180 Degree Elbow is made of duplex stainless steels, stainless steels, alloy steels, and more.

Alloy 20 180 Degree Elbow

Type | Alloy 20 180 Degree Elbow |

Size | SMLS Elbow 1/2"~24" (DN15 - DN600) Welded Elbow 1/2"~48" (DN15 - DN1200) |

Wall thickness |

sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, etc

|

Standards | ASME, ASTM, DIN, JIS, etc |

Material | Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc

|

Surface treatment | Transparent oil, rust-proof black oil or hot galvanized |

Applications | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

Alloy 20 180 Degree Elbow is like 45 or 90 degree elbow, but the flow direction change is 180 degree. It looks like the flow fluid get back to the same direction from the joint. The shape is like two 90 degree elbows welded together. It is also called “U bend” or “return bend”. The 180 degree elbow could be the long radius or short radius , both are used a lot in the industry application .

Standard | Alloy 20 |

UNS | N08020 |

Werkstoff Nr. | 2.4660 |

Chemical Composition Of Alloy 20 180 Degree Elbow

| Alloy 20 |

Ni | 32 – 38 |

Fe | Bal |

Cr | 19 – 21 |

Cu | 3 – 4 |

Mo | 2 – 3 |

Nb | 0.1 – 0.3 |

C | 0.02 max |

Mn | 1 – 2 |

P | 0.02 max |

S | 0.005 max |

Si | 0.7 max |

Mechanical & Physical Properties – Alloy 20 180 Degree Elbow

Density | 8.1 g/cm3 |

Melting Point | 1443 °C (2430 °F) |

Tensile Strength | Psi – 80000 , MPa – 551 |

Yield Strength (0.2%Offset) | Psi – 35000 , MPa – 241 |

Elongation | 30 % |

What are the characteristics of Alloy 20?

1、Resistant to pitting, crevice corrosion and stress corrosion cracking

2、Outstanding resistance to both reducing and oxidizing media3、Excellent resistance to oxidizing aqueous media4、Exceptional resistance to a wide variety of chemical process environments including strong oxidizers such as ferric acids, acetic anhydride, and seawater and brine solutions5、Resists the formation of grain-boundary precipitates in the weld heat-affected zone6、Excellent weldability

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

Alloy 20 180 Degree Elbow Packing & Shipping

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps,

pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality Alloy 20 180 Degree Elbow.

You can visit this website: www.tanell.net(Zhejiang Tanell industry technology Co., Ltd.)

If any inquiry about products, please feel free to contact us tan@tanell.com