Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

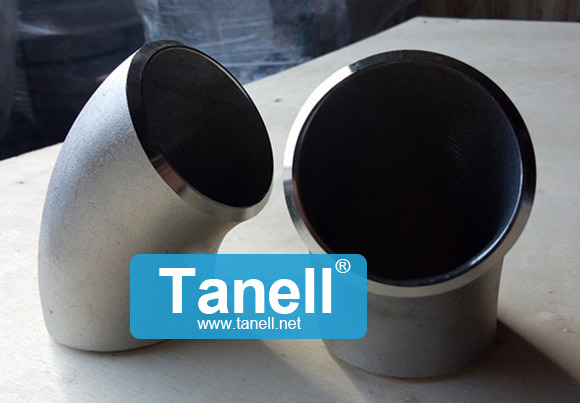

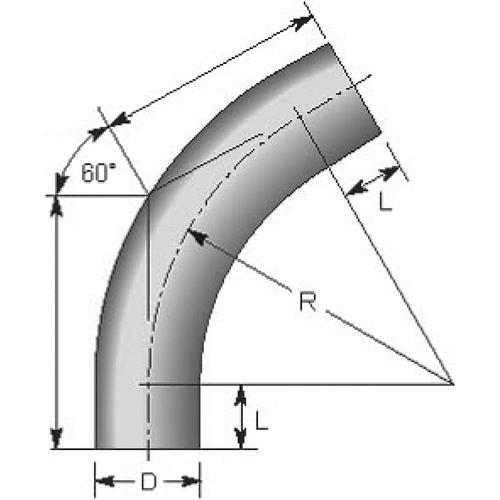

ASME B16.9 ASTM A403 316L 60 Degree Elbow SMLS 4 Inch SCH40S

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Quick Details

| Material: | 316L (S31603), etc | Technics: | Forged | Type: | 316L 60 Degree Elbow |

| Place of Origin: | Zhejiang, China (Mainland) | Model Number: | pipe bend | Brand Name: | Tanell |

| Connection: | Welding, Weld | Shape: | Equal | Head Code: | Round |

| Size: | 4 Inch (DN 100) | Standard Or Nonstandard: | standard | Arrange: | 60 degree |

Packaging & Delivery

| Packaging Detail: | Plywood case or fumigation woodern case |

| Delivery Detail: | Usually 2-10 days depend on the quantity |

Specifications

ASME B16.9 ASTM A403 316L 60 Degree Elbow SMLS 4 Inch SCH40S

1)Matarial: 316L (S31603), etc

2)Size: 4 Inch (DN 100)

3)Standard: ASTM, etc

4)Connection:Welded,Clamped,unioned,maled, etc

5)Type: 60 Degree Elbow

China Elbow Manufacturer Yaang offers ASME B16.9 ASTM A403 316L 60 Degree Elbow SMLS, 4 inch (DN100), WT: SCH40S, Material: 316L (S31603).

Composition ranges for 316L stainless steel

Composition ranges for 316L stainless steel

Grade |

| C | Mn | Si | P | S | Cr | Mo | Ni | N |

316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 |

Type | 316L 60 Degree Elbow |

Size | 1/2”~100" (DN15~DN2500) |

Wall thickness | Sch10, sch20, sch30, std, sch40, sch60, xs, etc |

Standards | ANSI, ASTM, DIN, JIS, etc |

Material | Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Super Duplex Stainless Steel: S32750/2507, UNS32760, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

Surface treatment | Transparent oil, rust-proof black oil or hot galvanized |

Applications | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

ASME B16.9 ASTM A403 316L 60 Degree Elbow is used to change the direction of run of pipe. It advantage is can matach long distance transition requirements, so it is commonly that bends dimension according to customer design.

Wall Thickness Of Elbows

The weakest point on an elbow is the inside radius. ASME B16.9 only standardizes the center to face dimensions and some "squareness" dimensional tolerances. The wall thickness at the weld line location even is standardized, but not through the rest of an elbow. The standard states that the minimum tolerance will be within 12.5% of the minimum ordered wall thickness of the pipe. A maximum tolerance is specified only at the ends of the fitting.

Many providers of buttweld elbows (and tees) provide one schedule greater thickness so that sufficient wall thickness, after forming, remains.

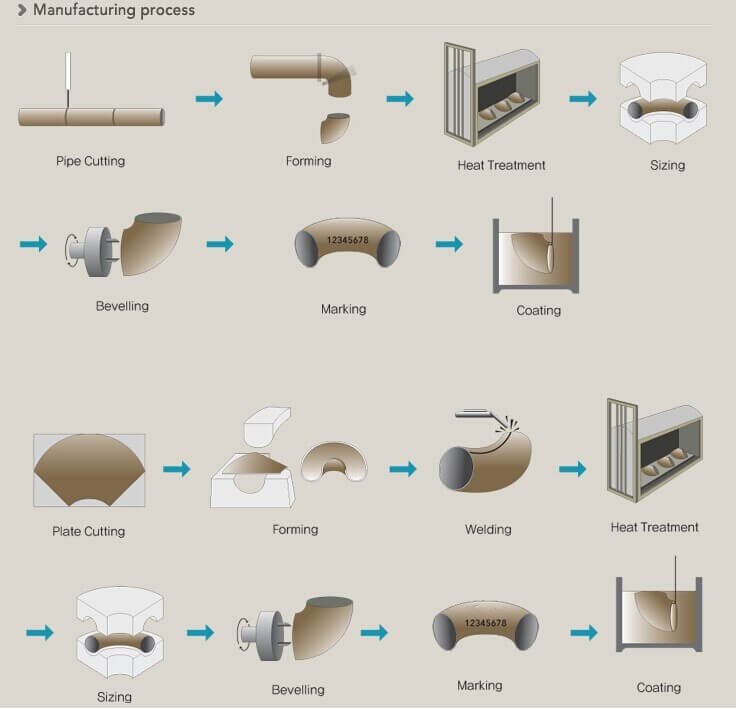

Production process of Elbow

If any inquiry about products, please feel free to contact us tan@tanell.com

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.