Quick Details

Material: Nickel 200/Nickel 201 (UNS N02200/UNS N02201) Round Bar

Technics: Cold Formed

Type: SMLS CON RED

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Tanell

Connection: Welding

Shape: Equal

Head Code: Round

Products

Credibility ,

Material: Nickel 200/Nickel 201 (UNS N02200/UNS N02201) Round Bar

Technics: Cold Formed

Type: SMLS CON RED

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Tanell

Connection: Welding

Shape: Equal

Head Code: Round

| Packaging Detail: | Plywood case or fumigation woodern case |

| Delivery Detail: | Usually 2-10 days depend on the quantity |

1. Size: 4" - 1-1/2" (DN100-DN40)

2. Wall thickness: SCH80

China Concentric Reducer Manufacturer Tanell supplies ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer, 4 Inch - 1-1/2 Inch, SCH80.

Nickel 200 and Nickel 201 are solid solution strengthened, commercially pure wrought materials. Typically, the elemental restrictions of both alloys are combined into one, dual-certified chemistry resulting in a single alloy with the desired characteristics of both alloys. Applications where Nickel 200/201 can be used include chemical processing and storage, synthetic fiber production, and processes where sodium hydroxide and fluorine is used. Other applications include aerospace and defense as well as food processing. Nickel 200/201 has exceptional resistance to caustic alkalies at various temperatures and concentrations.

When operating temperatures are expected to exceed 600°F, carbon content becomes critical. The lower carbon content of Nickel 201 makes the material resistant to graphitization and therefore less subject to embrittlement. Pressure vessels and vessel components can be constructed from Nickel 201 according to the ASME Boiler and Pressure Vessel Code, Section VIII, Division 1 for use up to 1250°F.

Resistance to Corrosion

Both Nickel 200 and 201 offer corrosion resistance in reducing and neutral media as well as in oxidizing atmospheres provided that the oxidizing media allows the formation of a passive oxide film. This oxide film accounts for the materials excellent resistance in caustic environments.

Fabrication and Heat Treatment

All hot working and cold working practices can be utilized when shaping Nickel 200/201. Hot working temperatures should be between 1200°F and 2250°F with heavy forming to be performed at temperatures

above 1600°F. Annealing should be performed at a temperature between 1300°F and 1600°F. Care should be taken when choosing the anneal temperature and time-at-temperature for this can greatly influence the mechanical properties and structure of the material.

| STANDARD | UNS | WERKSTOFF NR. | BS | AFNOR | JIS | GOST | EN |

| Nickel 200 | N02200 | 2.4066 | NA 11 | N-100M | NW 2200 | НП-2 | Ni 99.2 |

| Nickel 201 | N02201 | 2.4068 | NA 12 | - | NW 2201 | НП-2 | LC-Ni 99 |

Chemical Composition, % of Inconel 600 (UNS N06600/Alloy 600)

| Nickel 200 (UNS N02200) | 99.0 min | .40 max | .25 max | .15 max | .35 max | .01 max | .35 max |

| NI | FE | CU | C | MN | S | SI | |

| Nickel 201 (UNS N02201) | 99.0 min | .40 max | .25 max | .02 max | .35 max | .01 max | .35 max |

| Size: | 4" - 1-1/2" (DN100-DN40) |

| Material: | Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Super Duplex Stainless Steel: S32750/2507, UNS32760, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C276, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

| Standard: | ASME/DIN/ISO/, etc |

| Connection: | Welding |

| Wall thickness: | SCH40 |

| Finish: | Mirror polish, semi bright etc |

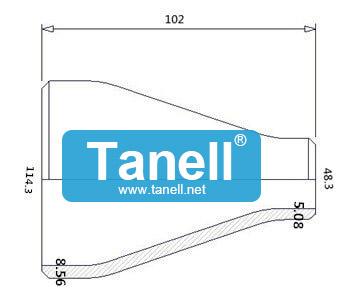

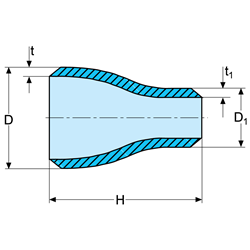

| NPS | O.D. D | O.D. D1 | Len H |

| 4"-1.1/2" | 114.3 | 48.3 | 102 |

CON RED

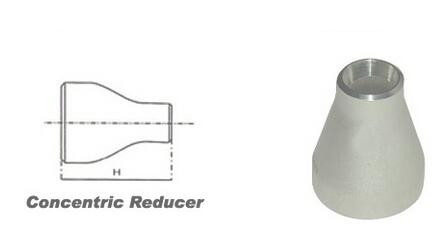

ASME B16.9 ASTM B366 Nickel Alloy 200/201 Concentric Reducer is used to join pipes or tubes sections on the same axis. They provide an in-line conical transition between pressurized pipes of differing diameters. A Nickel Alloy 200/201 Concentric Reducer can be a single diameter change or a multiple diameter change. The pipes cannot recognize what the outside configuration of the pipe reducer looks like. The pipe flow is affected by the inside diameter conical transition configuration which can be axially moved and externally reconfigured to provide for more economical reducer fittings. Thus, Nickel Alloy 200/201 Concentric Reducers of unequal size but have a common centerline. In other words, it is a type of pipe fitting with different size ends to join pipes of different diameter that joins pipe sections on the same axis.

Nickel Alloy 200/201 Concentric Reducer is designed with the small and large diameters on opposite ends and joined by a cone shaped transition section. They are available in both seamless and welded construction.

Use of 200/201 Concentric Reducer is as follows:

Nickel Alloy 200/201 Concentric Reducer will transition gracefully between the piping and the pump.

The Nickel Alloy 200/201 Concentric Reducer helps in transporting slurries or abrasive liquids.

They are useful in services where cavitation is present.

When transporting between flanges or pipes of different ratings and wear protection is necessary, concentric reducers are ideal.

Nickel Alloy 200/201 Concentric Reducers are used in discharge of the pump.

Application range: Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.