Average Elevated Temperature Tensile Properties

| Temperature, °F | Ultimate Tensile Strength, ksi | .2% Yield Strength, ksi |

|---|---|---|

| 68 | 84 | 38 |

| 400 | 62 | 20.5 |

| 600 | 62 | 18 |

| 800 | 62 | 17 |

| 1000 | 59.5 | 16.5 |

| 1200 | 45.5 | 16 |

| 1400 | 27.5 | 14 |

Products

Credibility ,

Quick Details

| Material: | 321 | Technics: | Forged | Type: | Socket Welding Cap |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

| Packaging Detail: | Plywood case or fumigation woodern case |

| Delivery Detail: | Usually 2-10 days depend on the quantity |

Specifications

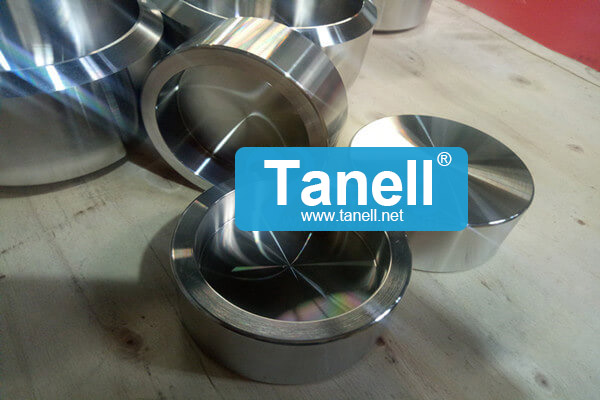

ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS

1) Size: 2" (DN50)

2) WT: 6.04 - 6.93

3) Material: 321 (UNS S32100)

China Socket Welding Cap Manufacturer Tanell supplies ASME B16.11 ASTM A182 F321 Socket Welding Cap, 2 Inch, 3000LBS.

| Cr | Ni | Mo | Cu | Ti | C | Mn | Si | P | S | N | Fe | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIN | 17.0 | 9.0 | - | - | 5x(C+N) | - | - | 0.25 | - | - | - | - |

| MAX | 19.0 | 12.0 | 0.75 | 0.75 | 0.70 | 0.08 | 2.0 | 1.0 | 0.04 | 0.03 | 0.1 | Bal |

Average Elevated Temperature Tensile Properties

| Temperature, °F | Ultimate Tensile Strength, ksi | .2% Yield Strength, ksi |

|---|---|---|

| 68 | 84 | 38 |

| 400 | 62 | 20.5 |

| 600 | 62 | 18 |

| 800 | 62 | 17 |

| 1000 | 59.5 | 16.5 |

| 1200 | 45.5 | 16 |

| 1400 | 27.5 | 14 |

Description Of ASME B16.11 ASTM A182 F321 Socket Welding Cap

Type | F321 Socket Welding Cap |

Size | SMLS Elbow 1/2"~24" (DN15 - DN600) Welded Elbow 1/2"~48" (DN15 - DN1200) |

Wall thickness | sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, etc |

Standards | ASME, ASTM, DIN, JIS, etc |

Material | Carbon Steel: ASTM: SA105N/A105, ASTM SA350 LF2,etc Stainless Steel: ASTM A182 F304/304L/316/316L, etc Alloy Steel: ASTM A182 F1/F5/F9/F11/F22/F91, Etc. Duplex stainless steel: ASTM A182 F51/F53/F55/F60, etc Nicke alloys: Nickel 200, Monel 400, Inconel 600/625, Incoloy 825/800, Hastelloy C276, Hastelloy C22, Hastelloy B1/B2/B3, Alloy 20, etc Cu-Ni: 90/10,70/30, etc |

Surface treatment | Transparent oil, rust-proof black oil or hot galvanized |

Applications | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

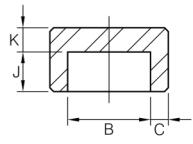

| Nominal Pipe Size | Socket Bore Diameter2 (B) | Socket Wall Thickness1 (C) | End Wall Thickness (Kmin) | Depth of Socket3 (J) | ||

|---|---|---|---|---|---|---|

| 3000Lbs | 6000Lbs | 3000Lbs | 6000Lbs | |||

| 1/8" | 11.2 10.8 | 3.18 3.18 | 3.96 3.43 | 4.8 | 6.4 | 9.5 |

| 1/4" | 14.6 14.2 | 3.78 3.30 | 4.60 4.01 | 4.8 | 6.4 | 9.5 |

| 3/8" | 18.0 17.6 | 4.01 3.50 | 5.03 4.37 | 4.8 | 6.4 | 9.5 |

| 1/2" | 22.2 21.8 | 4.67 4.09 | 5.97 5.18 | 6.4 | 7.9 | 9.5 |

| 3/4" | 27.6 27.2 | 4.90 4.27 | 6.96 6.04 | 6.4 | 7.9 | 12.5 |

| 1" | 34.3 33.9 | 5.69 4.98 | 7.92 6.93 | 9.6 | 11.2 | 12.5 |

| 1 1/4" | 43.1 42.7 | 6.07 5.28 | 7.92 6.93 | 9.6 | 11.2 | 12.5 |

| 1 1/2" | 49.2 48.8 | 6.35 5.54 | 8.92 7.80 | 11.2 | 12.7 | 12.5 |

| 2" | 61.7 61.2 | 6.93 6.04 | 10.92 9.50 | 12.7 | 15.7 | 16.0 |

| 2 1/2" | 74.4 73.9 | 8.76 7.67 | - - | 15.7 | 19.0 | 16.0 |

| 3" | 90.3 89.8 | 9.52 8.30 | - - | 19.0 | 22.4 | 16.0 |

| 4" | 115.7 115.2 | 10.69 9.35 | - - | 22.4 | 28.4 | 19.0 |

The lower and upper values for each dimension are respectively the average and minimum thicknesses required. The average thickness cannot be lower than the value mentioned. The minimum values are allowed in limited areas.

The lower and upper values for each dimension are respectively the minimum and maximum tolerances.

The dimensions are in millimeters

Source : ASME B16.11 - 2009

Pipe and Tubes for petrochemical industry

Oil & Gas industry

Pharmaceutical industry

Food industry

Aviation and aerospace industry

Architectural decoration industry etc

321 Stainless is readily welded by all common methods including submerged arc. Appropriate weld fillers are most often specified as AWS E/ER 347 or E/ER 321.

This alloy is generally considered to have comparable weldability to 304 and 304L stainless with the main difference being the titanium addition which reduces or prevents carbide precipitation during welding.

1) Packing Method:

Normal packing: plastic film or bubble paper wrapped on product's surface ,protect ends with caps , pack with wooden case or load on fumifation plywood pallet .

Custom made as customers request .

2) Shipping Way:

Usually by Sea, By Air, By Train or River-and-Sea Coordinated Transport.

As per customer's request.

Where can we find the high quality ASME B16.11 ASTM A182 F321 Socket Welding Cap 2 Inch 3000LBS.

You can visit this website: tanell.net(Zhejiang Tanell Pipes&Fitting Co., Ltd)

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.