Specifications

Material: stainless steel 304 or 316L, etc

Size: ID:1"~120" Len:2"~780" or as requirement

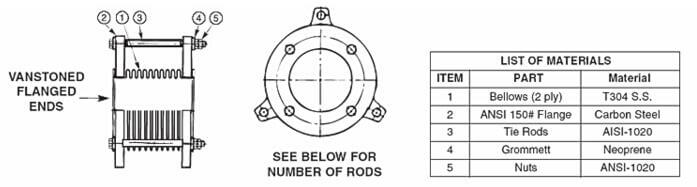

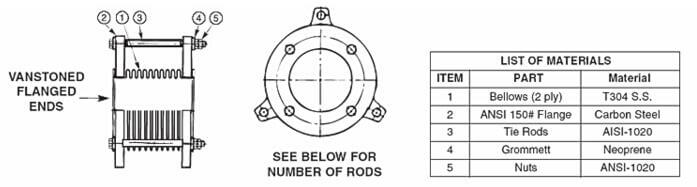

Construction: bellows+(or braid)+flange

Use: Quick disconnect cam-and groove fittings, fixed and floating flanges (ANSI, PN, BS, JP standards) and other specialty items such as Victaulic.

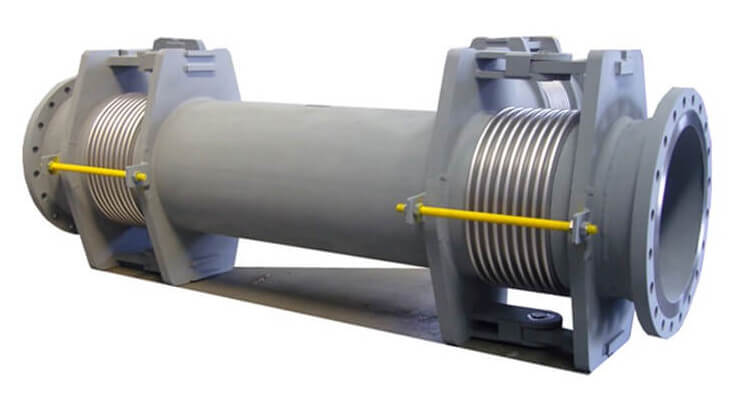

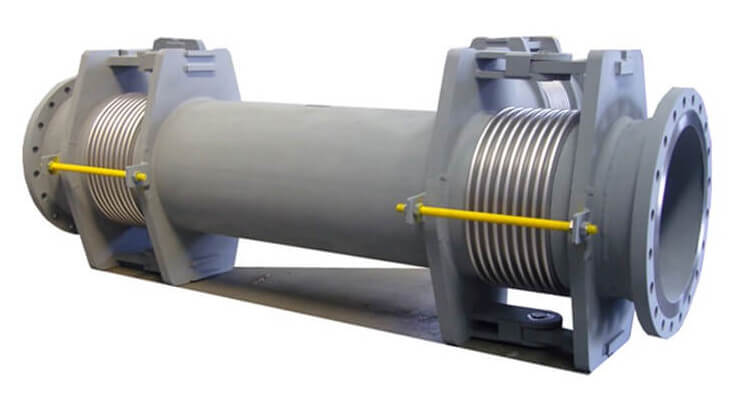

China Bellow Expansion Joint Manufacturer Tanell supplies Stainless Steel Flanged Bellow Expansion Joint.

Stainless Steel Falanged Bellow Expansion Joint |

Diameter (mm) | Material thickness (mm) | Outer diameter (mm) | Wave distance (mm) | Length (mm) | Bolt number (n) | Flanger diameter (mm) | Each wave displcement (mm) | Working pressure (Mpa) |

80 | 0.5~1.0 | 105 | 14 | 109~207 | 4~6 | 160 | 1.3~0.6 | 0.8~3 |

95 | 0.5~1.0 | 115 | 15 | 119~217 | 6~8 | 180 | 0.9~0.4 | 1.2~3.5 |

110 | 0.5~1.0 | 143 | 16 | 188~268 | 6~8 | 190 | 2.2~0.8 | 0.4~1.6 |

132 | 0.5~1.2 | 168 | 14 | 177~247 | 6~8 | 215 | 2.3~0.7 | 0.3~2.7 |

150 | 0.5~1.5 | 190 | 20 | 180~310 | 8~10 | 250 | 3.0~1.0 | 0.3~1.4 |

174 | 0.5~1.5 | 220 | 20 | 190~250 | 8~10 | 270 | 4.0~1.3 | 0.2~1.7 |

182 | 0.5~1.2 | 210 | 18 | 179~269 | 8~12 | 270 | 1.6~0.7 | 0.6~2.4 |

200 | 0.5~2.0 | 250 | 30 | 235~335 | 8~12 | 310 | 4.1~1.3 | 0.2~3.0 |

215 | 0.8~1.5 | 260 | 25 | 163~238 | 8~12 | 320 | 4.0~1.2 | 0.2~2.0 |

220 | 0.5~2.0 | 290 | 30~50 | 265~370 | 8~12 | 350 | 5.2~2.9 | 0.2~1.6 |

260 | 0.5~2.0 | 340 | 30~50 | 265~370 | 12~16 | 400 | 6.7~3.0 | 0.15~1.2 |

317 | 1.0~2.0 | 357 | 25 | 212~287 | 12~16 | 450 | 6.9~4.9 | 0.3~1.7 |

362 | 1.0~2.0 | 440 | 50 | 375 | 12~16 | 500 | 6.9~3.3 | 0.3~1.7 |

417 | 1.0~2.5 | 497 | 60 | 370 | 12~16 | 560 | 7.5~4.0 | 0.2~1.7 |

507 | 1.0~3.0 | 647 | 100 | 357 | 12~16 | 725 | 12~7.5 | 0.15~1.7 |

514 | 1.0~3.0 | 622 | 70 | 415 | 12~16 | 700 | 10~4 | 0.2~1.6 |

615 | 1.0~3.0 | 721 | 68 | 406 | 12~16 | 800 | 9.8~3.9 | 0.3~1.6 |

706 | 1.5~3.0 | 880 | 106 | 365 | 12~16 | 970 | 15~10 | 0.2~0.8 |

806 | 1.5~3.0 | 880 | 110 | 375 | 16~20 | 970 | 16~10 | 0.2~0.8 |

920 | 1.5~2.5 | 1045 | 74 | 186~334 | 16~20 | 1130 | 11~6 | 0.3~0.8 |

1004 | 1.5~2.5 | 1124 | 86 | 401 | 20~24 | 1215 | 9.5~6.5 | 0.3~0.8 |

1104 | 1.5~2.5 | 1260 | 80 | | 20~24 | 1350 | 9.5~6.5 | 0.2~0.5 |

1204 | 1.5~2.5 | 1374 | 85 | | 20~24 | 1470 | 9.5~6.5 | 0.15~0.45 |

1400 | 1.5~2.5 | 1590 | 95 | | 20~24 | 1680 | 22~13 | 0.1~0.3 |

1600 | 1.5~2.5 | 1790 | 95 | | 20~24 | 1880 | 22~13 | 0.1~0.25 |

A Bellow Expansion Joint or movement joint is an assembly designed to safely absorb the heat-induced expansion and contraction of construction materials, to absorb vibration, to hold parts together, or to allow movement due to ground settlement or earthquakes. They are commonly found between sections of buildings, bridges, sidewalks, railway tracks, piping systems, ships, and other structures.

Building faces, concrete slabs, and pipelines expand and contract due to warming and cooling from seasonal variation, or due to other heat sources. Before expansion joint gaps were built into these structures, they would crack under the stress induced.

WHAT IS THE DIFFERENCE BETWEEN A BELLOWS AND AN EXPANSION JOINT?

The terminology can be confusing and often words have no universally accepted meaning. We use the following definitions but the terms “bellows” and “expansion joint” are typically considered as interchangeable:

Expansion Joint - an expansion joint is a complete unit with metal bellows or rubber bellows and end fittings, plus, optionally, liner, cover and external hardware. Other terms used - compensator, flexible connector.

Rubber Bellows - the flexible element within a rubber expansion joint

Metal Bellows - the flexible element within a metal expansion joint

Liner - The liner fits within the expansion joint under the metal bellows or rubber bellows to prevent the flowing media directly impinging on the bellows, this reduces flow disturbance and allows the temperature of the bellows to be controlled in the design.

Application

1) Central air-conditioning

2) Diesel engine (ship) exhaust line

3) Long distance pipeline such as Gas, steam, water etc.

4) Thermal expansion in Steel mill

5) Pipelines

6) Turbines

7) Compressors

8) Blowers

9) Vacuum pumps

10) Heat exchangers

11) Hot water and fire protection system

12) Compressors inlet and outlet

Advantages of Flanged Bellow Expansion Joint

1) Easy to absorb the expansion movements

2) No direction changes of the flow

3) Minimum application area

4) Possible lateral and angular expansion absorption by the additional bellows.

5) To provide a non-stressed area where the pressure is not too high such as pump and compressor applications.

6) Low application costs

You can visit this website: tanell.net(Zhejiang Tanell Pipes&Fitting Co., Ltd)