What are the characteristics of Inconel 625?

1、Excellent corrosion resistance in reducing environments

2、Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

3、High nickel and molybdenum contents providing good corrosion resistance in reducing environments

4、Low carbon content which minimizes grain-boundary carbide precipitation during welding to in heat-affected zones of welded joints

5、Resistance to localized corrosion such as pitting and stress-corrosion cracking

6、One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

Design Features - UNS N06625 Inconel 625

1、Outstanding corrosion resistance and oxidizing environments.

2、Excellent resistance to pitting and stress-corrosion cracking.

3、Maintains corrosion resistance in welded joints.

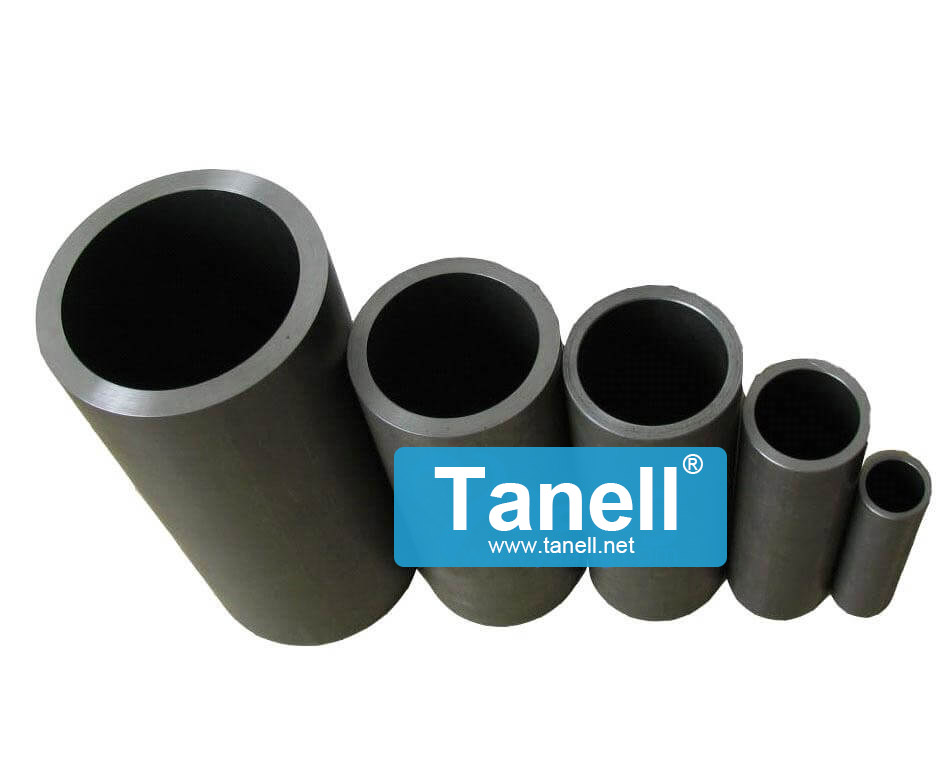

Application of Inconel 625 Seamless Pipe

1. Inconel 625 Pipes and Inconel 625 Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

5. Oil and Gas Pipeline industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce pipes with special specifications according to customers’ requirements;

Inconel 625 alloy can be forged, hot-upset and impact extruded. Although the alloy tends to work-harden, you can have it successfully spun, deep-drawn, press formed or punched. All of the common methods of welding can be used, although the oxyacetylene and submerged arc processes are not recommended when the fabricated item is for use in corrosion service.

Although there are several variations of the Hastelloy nickel alloy, Inconel 625 is by far the most widely used.

Inconel 625 is widely used in the most severe environments such as chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and recovery of sour natural gas.

While marking we choose a specific item number as well different color shade to differentiate steel grades. We mark Inconel 625 Seamless Pipe as needed with the most suitable & visible marking technique.

Packaging is an integral part of the product. It guarantees that the Inconel 625 Seamless Pipe is delivered to the customer in the required quality. For smaller orders the size of the Inconel 625 Seamless Pipe bundle depends on the no. of Tubes ordered, for larger orders the tubes are packed into individual bundles and in such a way that the maximum weight of 4000kg per bundle is not excedded. Bundle tied down with steel tape. Bundle tied down by steel strap underlaid by tapaten.

We can also provide Inconel Seamless Pipe wooden box packing, cardboard boxes, plastic wrapping, using hardened paper with PE meshing (used as protection against mechanical damages of tubes), into tapaten and polyethylene sheet etc.

Where can we find the high quality Inconel 625 Seamless Pipe.