You can visit this website: tanell.net(Zhejiang Tanell Pipes&Fitting Co., Ltd)

Ξ

Products

Credibility ,the lifeblood of enterprise!

PRODUCT SERIES

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Round Bar -

Tanell

UNS N10276 Hastelloy C276 Round Bar

- FOB Price USD 5,00- 30,000/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece/Ton

- Supply Ability 1000 Tons Per Month

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 7- 20 days

Detailed description

Quick Details

| Steel Grade: | Hastelloy C276 | Standard: | AISI,ASTM,etc | Dimensions: | Customized |

| Place of Origin: | Zhejiang, China (Mainland) | Brand Name: | Tanell | Model Number: | 200,300,400series |

| Technique: | Hot Rolled, Cold Rolled | Application: | Petroleum, chemical industries, etc | Type: | Hastelloy C276 Round Bar |

Packaging & Delivery

| Packaging Detail: | according to customer's require or export's standard |

| Delivery Detail: | 7 - 20 days after confirmation |

Specifications

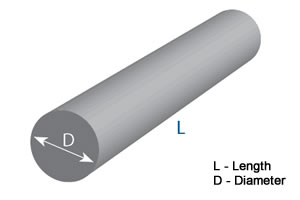

UNS N10276 Hastelloy C276 Round Bar

1.Standard: ASTM, AISI, etc

2.Material: 200,300,400series

3.Diameter: 2-300mm

4.Length: 2 - 13m

Nickel Alloy C276 and Hastelloy C276, commonly known as UNS N10276, is generally considered the most versatile corrosion resistant alloy available, comprised of nickel, molybdenum, chromium, iron and tungsten. These elements combined results outstanding corrosion resistant properties particularly crevice and pitting, allowing for its use in a broad range of corrosive environments. It displays tremendous resistance to many acids, including sulfuric, acetic, phosphoric, formic, nitric, hydrochloric, and hydrofluoric compounds, which is why it is so popular in chemical and food processing environments including strong oxidizers.

Nickel Alloy C276 is a fairly normal alloy in the sense that it can be impact extruded, forged and hot upset forged by conventional means. It has good machineability as it can be successfully press formed, spun, punched or deep-drawn; however it does have a tendency to work harden as is true of the nickel base alloys in general. It can be welded by all common methods such as gas metal-arc, resistance welding, gas tungsten-arc or shielded metal-arc. Applying minimum heat input combined with sufficient penetration can reduce hot cracking to avoid the possibility of carburization. Two methods that are not recommended are submerged arc welding and oxyacetylene welding when the component is to be used in a corrosive environment. A welding advantage of Nickel Alloy C-276 is that it can be used in the “as-welded” condition without further heat treatment for most corrosive applications.

UNS N10276 Hastelloy C276 Round Bar

| Standard | UNS | EN | Werkstoff Nr. | GOST | JIS | OR |

| Hastelloy C276 | N10276 | NiMo16Cr15W | 2.4819 | ХН65МВУ | NW 0276 | ЭП760 |

Chemical Composition - UNS N10276 Hastelloy C276 Round Bar

| C | Co | Cr | Fe | Mn | Mo | Ni | P | S | Si | V | W |

| Max | Max | Max | Max | Max | Max | Max | |||||

| 0.01% | 2.5% | 14.5% -16.5% | 4-7% | 1.0% | 15 -17% | BAL | .04% | 0.03% | 0.08% | 0.35% | 3-4.5% |

Mechanical Properties of UNS N10276 Hastelloy C276 Round Bar

Typical Room Temperature Tensile Properties of Annealed Material

| Product Form | Tensile (ksi) | .2% Yield (ksi) | Elongation % |

| Bar | 110.0 | 52.6 | 62 |

UNS N10276 Hastelloy C276 Round Bar is a super alloy of nickel, chromium and manganese. To enhance the resistance towards corrosion, tungsten is added. It enables the alloy to exhibit this property in a wide range of temperatures. Nickel and molybdenum help in preventing pitting and crevice formation, while chromium prevents oxidation. Carbon content is kept low so that corrosion resistance is maintained even after welding. It is suitable for uses in chemical application in the welded state. It is also resistant to grain boundary precipitation. It is also resistant to corrosion in reducing environments.

Industries that use UNS N10276 Hastelloy C276 Round Bar include:

1. Pipe and Tubes for petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

5. Oil and Gas Pipeline industry

Where can we find the high quality UNS N10276 Hastelloy C276 Round Bar.

Related products:

More>>

|

|

|

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.