Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

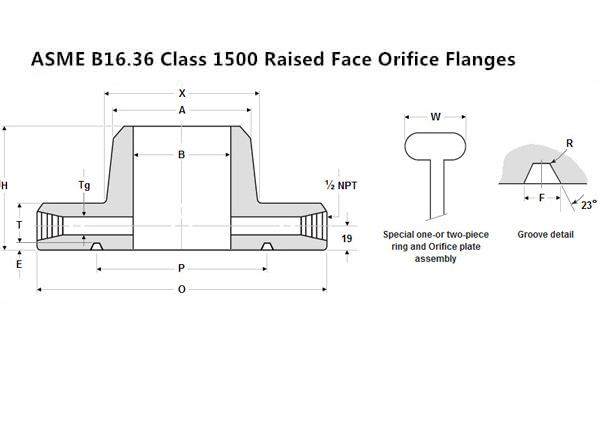

ASME B16.36 Class 1500 Raised Face Orifice Flanges

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Size: 1/2" (DN15) - 100" (DN2500)

Brand Name: Tanell

BS4504, BS4504, BS1560, BS10, etc

An Orifice Flange is intended for use instead of standard pipe Flanges when an orifice plate or flow nozzle must be installed. Pairs of pressure tapings are machined into the Orifice Flange, making separate orifice carriers or tapings in the pipe wall unnecessary.

Orifice Flanges cover all standard sizes and ranges, and all common Flange materials.

ASME B16.36 Ring Type Joint Orifice Flanges

ASME B16.36 Class 600 Ring Type Joint Orifice Flanges

ASME B16.36 Class 900 Ring Type Joint Orifice Flanges

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges

ASME B16.36 Class 2500 Ring Type Joint Orifice Flanges

Orifice Flanges Material & Grades:

Stainless Steel Orifice Flanges: ASTM A182, A240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Carbon Steel Orifice Flanges: ASTM / ASME A/SA 105 ASTM / ASME A 350 , ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F70

Alloy Steel Orifice Flanges: ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Duplex Steel Orifice Flanges: ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Super Duplex Orifice Flanges: ASTM / ASME A/SA 182, A240 F 44, F 45, F51, F 53, F 55, F 60, F 61

Nickel Alloy Orifice Flanges: Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), etc

Copper Alloy Orifice Flanges: UNS No. C10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu-Ni-70/30)

Low Temperature Carbon Steel Orifice Flanges: ASTM A350, LF2, LF3

Applications Of ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are used in Chemical and petrochemical processing.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are used in electronics.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are used in processing equipment for maintaining product purity in handling foods, synthetic fibers.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are used in marine and offshore engineering.

Characteristics of ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are highly resistant to various reducing chemicals.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are excellent resistance to caustic alkalies.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are high electrical conductivity.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are excellent corrosion resistance to distilled and natural waters.

ASME B16.36 Class 1500 Raised Face Orifice Flanges are resistance to neutral and alkaline salt solutions.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are excellent resistance to dry fluorine.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are widely used to handle caustic soda.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges are good thermal, electrical and magnetostrictive properties.

ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges offer some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations.

Dimensions of ASME B16.36 Class 1500 Ring Type Joint Orifice Flanges

| NPS | OUT SIDE DIA | MIN THK FLG | HT FLG | GRV NO | PITCH DIA | GRV DEPTH | GRV WIDTH | R BTM | HT OVAL RING | HUB DIA | HUB DIA | DIA OF TAP | BOLT CIRCLE | NO OF BOLTS | DIA OF HOLES | DIA STUD BOLTS | STUD BOLT L |

| O | T | H | P | E | F | R | W | X | A | Tg | |||||||

| 1 | 150 | 38.1 | 83 | R16 | 50.80 | 6.35 | 8.74 | 0.8 | 25.4 | 52 | 33.5 | 6.4 | 101.6 | 4 | 1 | 7/8 | 160 |

| 1½ | 180 | 38.1 | 89 | R20 | 68.27 | 6.35 | 8.74 | 0.8 | 25.4 | 70 | 48.3 | 6.4 | 123.8 | 4 | 1 1/8 | 1 | 165 |

| 2 | 215 | 38.1 | 102 | R24 | 95.25 | 7.92 | 11.91 | 0.8 | 27.0 | 105 | 60.3 | 6.4 | 165.1 | 8 | 1 | 7/8 | 165 |

| 2½ | 245 | 41.3 | 105 | R27 | 107.95 | 7.92 | 11.91 | 0.8 | 27.0 | 124 | 73.0 | 6.4 | 190.5 | 8 | 1 1/8 | 1 | 180 |

| 3 | 265 | 47.7 | 117 | R35 | 136.53 | 7.92 | 11.91 | 0.8 | 27.0 | 133 | 88.9 | 9.5 | 203.2 | 8 | 1 1/4 | 1 1/8 | 185 |

| 4 | 310 | 54.0 | 124 | R39 | 161.93 | 7.92 | 11.91 | 0.8 | 27.0 | 162 | 114.3 | 12.7 | 241.3 | 8 | 1 3/8 | 1 1/4 | 215 |

| 6 | 395 | 82.6 | 171 | R46 | 211.14 | 9.52 | 13.49 | 1.5 | 28.6 | 229 | 168.3 | 12.7 | 317.5 | 12 | 1 1/2 | 1 3/8 | 280 |

| 8 | 485 | 92.1 | 213 | R50 | 269.88 | 11.13 | 16.66 | 1.5 | 33.3 | 292 | 219.1 | 12.7 | 393.7 | 12 | 1 3/4 | 1 5/8 | 310 |

| 10 | 585 | 108.0 | 254 | R54 | 323.85 | 11.13 | 16.66 | 1.5 | 33.3 | 368 | 273.0 | 12.7 | 482.6 | 12 | 2 | 1 7/8 | 355 |

| 12 | 675 | 123.9 | 283 | R58 | 381.00 | 14.27 | 23.01 | 1.5 | 39.7 | 451 | 323.8 | 12.7 | 571.6 | 16 | 2 1/8 | 2 | 400 |

| 14 | 750 | 133.4 | 298 | R63 | 419.10 | 15.88 | 26.97 | 2.4 | 44.4 | 495 | 355.6 | 12.7 | 635.0 | 16 | 2 3/8 | 2 1/4 | 445 |

| 16 | 825 | 146.1 | 311 | R67 | 469.90 | 17.48 | 30.18 | 2.4 | 50.8 | 552 | 406.4 | 12.7 | 704.8 | 16 | 2 5/8 | 2 1/2 | 485 |

| 18 | 915 | 162.0 | 327 | R71 | 533.40 | 17.48 | 30.18 | 2.4 | 50.8 | 597 | 457.2 | 12.7 | 774.7 | 16 | 2 7/8 | 2 3/4 | 535 |

| 20 | 985 | 177.8 | 356 | R75 | 584.20 | 17.48 | 33.32 | 2.4 | 54.0 | 641 | 508.0 | 12.7 | 831.8 | 16 | 3 1/8 | 3 | 570 |

| 24 | 1170 | 203.2 | 406 | R79 | 692.15 | 20.62 | 36.53 | 2.4 | 58.7 | 762 | 609.6 | 12.7 | 990.6 | 16 | 3 5/8 | 3 1/2 |

|

|

|

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.