1. Material: Hastelloy C276 (UNS N10276)

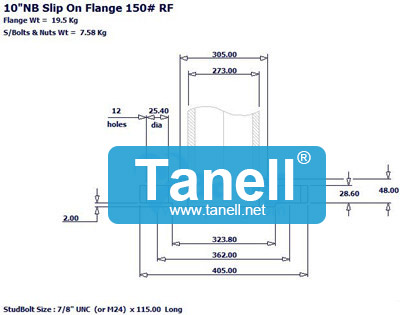

2. Size: 10" (DN250)

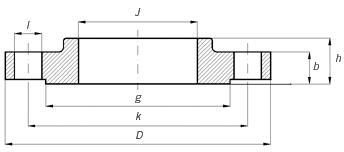

3. Standard: ASME B16.5

4. Pressure: 150#

China Flange Manufacturer Tanell offers ASME B16.5 ASTM B564 Hastelloy C276 Slip On Flange RF, 10 Inch, CL150.

Hastelloy C276 is a solid-solution-strengthened, nickel-molybdenum-chromium alloy with a small amount of tungsten, which exhibits excellent corrosion resistance in an assortment of harsh environments. Applications include and are not limited to, stack liners, ducts, dampers, scrubbers, stack-gas re-heaters, heat exchangers, reaction vessels and evaporators. Industries where C276 can be utilized are petrochemical and chemical processing, power generation, pharmaceutical, pulp and paper production and waste treatment to name a few.

Specifications - ASTM B564 UNS N10276 Hastelloy C276 Slip On Flange

| ASTM | B619, B366, B564 |

| ASME | SB619, SB366, SB564 |