Ξ

Products

Credibility ,the lifeblood of enterprise!

PRODUCT SERIES

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

Welding Neck Flanges -

Tanell

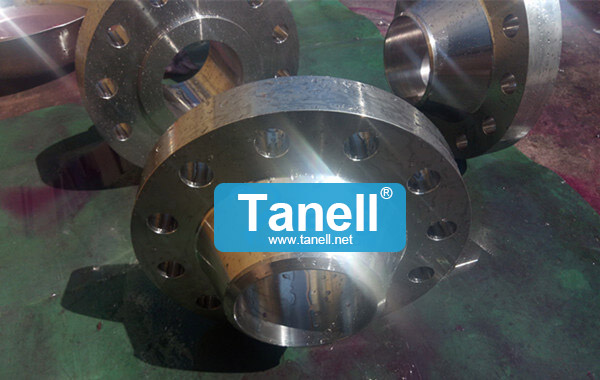

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Detailed description

Quick Details

Size: 6" (DN150)

Material: Inconel 625 (Nickel Alloy 625/UNS N06625)

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Tanell

Standard or Nonstandard: Standard

Technics: Forged

Connection: Welding

Shape: Round

Standard: ASME B16.5

Type: Alloy 625 WNST Flange

Size: 6" (DN150)

Material: Inconel 625 (Nickel Alloy 625/UNS N06625)

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Tanell

Standard or Nonstandard: Standard

Technics: Forged

Connection: Welding

Shape: Round

Standard: ASME B16.5

Type: Alloy 625 WNST Flange

Packaging & Delivery

| Packaging Details: | Seaworthy plywood case or as customer requests |

|---|---|

| Delivery Detail: | 2 - 10 days after receiving the deposit |

Specifications

ASME B16.5 ASTM B564 UNS N06625 WNST Flange 6 Inch SCH40S CL900

1. Material: Inconel 625 (Nickel Alloy 625/UNS N06625) 2. Size: 6" (DN150)

3. Standard: ASME B16.5

4. Pressure: 900#

Inconel 625 (Nickel Alloy 625/UNS N06625) is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Its outstanding strength and toughness is due to the addition of niobium which acts with the molybdenum to stiffen the alloy’s matrix. Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN. This alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Some typical applications Inconel 625 is used in are chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

China Flange Manufacturer Tanell supplies ASME B16.5 ASTM B564 UNS N06625 WNST Flange, 6 Inch, SCH40S, CL900.

Composition ranges for Inconel 625 (Nickel Alloy 625/UNS N06625) grade stainless steels

This nickel-based product is supplemented by various alloys and metals that support its performance characteristics. Type analysis specifications are as follows:

CO2 Cr Fe Si Mn S P Mo Ti Co Nb (Cb) Al 0-.10 20.0-23.0 0-5.0 0-5.0 0-5.0 0-0.015 0-0.015 8.0-10.0 0-0.40 0-1.0 3.15-4.15 0-0.40

1. Material: Inconel 625 (Nickel Alloy 625/UNS N06625)

3. Standard: ASME B16.5

4. Pressure: 900#

Inconel 625 (Nickel Alloy 625/UNS N06625) is a corrosion and oxidation resistant nickel alloy that is used both for its high strength and outstanding aqueous corrosion resistance. Its outstanding strength and toughness is due to the addition of niobium which acts with the molybdenum to stiffen the alloy’s matrix. Alloy 625 has excellent fatigue strength and stress-corrosion cracking resistance to chloride ions. This nickel alloy has excellent weldability and is frequently used to weld AL-6XN. This alloy resists a wide range of severely corrosive environments and is especially resistant to pitting and crevice corrosion. Some typical applications Inconel 625 is used in are chemical processing, aerospace and marine engineering, pollution-control equipment, and nuclear reactors.

China Flange Manufacturer Tanell supplies ASME B16.5 ASTM B564 UNS N06625 WNST Flange, 6 Inch, SCH40S, CL900.

Composition ranges for Inconel 625 (Nickel Alloy 625/UNS N06625) grade stainless steels

This nickel-based product is supplemented by various alloys and metals that support its performance characteristics. Type analysis specifications are as follows:

| CO2 | Cr | Fe | Si | Mn | S | P | Mo | Ti | Co | Nb (Cb) | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0-.10 | 20.0-23.0 | 0-5.0 | 0-5.0 | 0-5.0 | 0-0.015 | 0-0.015 | 8.0-10.0 | 0-0.40 | 0-1.0 | 3.15-4.15 | 0-0.40 |

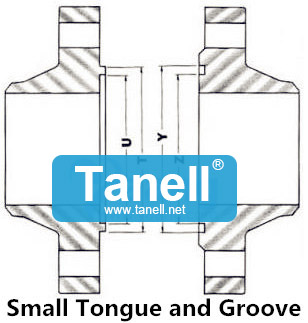

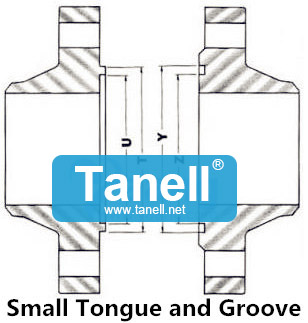

Nominal Size (in.) RF, LJ, Large Male and Large Tongue Small Male (3) Small Tongue ID of Large and Small Tongue Large Female and Large Groove Small Female (3) Small Groove ID of Large and Small Groove Raised Face 150 and 300 Pound Standards (2) RF, Large and Small Male and Tongue 400, 600, 900, 1500, & 2500 lb. Standards (2) Depth of Groove or Female

R S T U W X Y Z

1/2 1.38 0.72 1.38 1 1.44 0.78 1.44 0.94 0.06 0.25 0.19 3/4 1.69 0.94 1.69 1.31 1.75 1 1.75 1.25 0.06 0.25 0.19 1 2 1.19 1.88 1.5 2.06 1.25 1.94 1.44 0.06 0.25 0.19 1 1/4 2.5 1.5 2.25 1.88 2.56 1.56 2.31 1.81 0.06 0.25 0.19 1 1/2 2.88 1.75 2.5 2.12 2.94 1.81 2.56 2.06 0.06 0.25 0.19 2 3.62 2.25 3.25 2.88 3.69 2.31 3.31 2.81 0.06 0.25 0.19 2 1/2 4.12 2.69 3.75 3.38 4.19 2.75 3.81 3.31 0.06 0.25 0.19 3 5 3.31 4.62 4.25 5.06 3.38 4.69 4.19 0.06 0.25 0.19 3 1/2 5.5 3.81 5.12 4.75 5.56 3.88 5.19 4.69 0.06 0.25 0.19 4 6.19 4.31 5.69 5.19 6.25 4.38 5.75 5.12 0.06 0.25 0.19 5 7.31 5.38 6.81 6.31 7.38 5.44 6.88 6.25 0.06 0.25 0.19 6 8.5 6.38 8 7.5 8.56 6.44 8.06 7.44 0.06 0.25 0.19 8 10.62 8.38 10 9.38 10.69 8.44 10.06 9.31 0.06 0.25 0.19 10 12.75 10.5 12 11.25 12.81 10.56 12.06 11.19 0.06 0.25 0.19 12 15 12.5 14.25 13.5 15.06 12.56 14.31 13.44 0.06 0.25 0.19 14 16.25 13.75 15.5 14.75 16.31 13.81 15.56 14.69 0.06 0.25 0.19 16 18.5 15.75 17.62 16.75 18.56 15.81 17.69 16.69 0.06 0.25 0.19 18 21 17.75 20.12 19.25 21.06 17.81 20.19 19.19 0.06 0.25 0.19 20 23 19.75 22 21 23.06 19.81 22.06 20.94 0.06 0.25 0.19 24 27.25 23.75 26.25 25.25 27.31 23.81 26.31 25.19 0.06 0.25 0.

Regular facing for 150 and 300 lb. Steel flanged fittings and flange standards is a 1/16 inch raised face included in the minimum flange thickness. A 1/16 inch raised face is also permitted on the 400, 600, 900, 1500, and 2500 Lb. Flange standards, but it must be added to the minimum flange thickness.Regular facing for 400, 600, 900, 1500, and 2500 lb. Flange standards is a ¼ inch raised face not included in minimum flange thickness dimensions.Care should be taken in the use of joints of these dimensions, (they apply particularly on lines where the joint is made on the end of pipe) to insure that pipe used is thick enough to permit sufficient bearing surface to prevent crushing the gasket. Threaded companion flanges are furnished with plain face and are threaded with American Standard Locknut Thread.

| Nominal Size (in.) | RF, LJ, Large Male and Large Tongue | Small Male (3) | Small Tongue | ID of Large and Small Tongue | Large Female and Large Groove | Small Female (3) | Small Groove | ID of Large and Small Groove | Raised Face 150 and 300 Pound Standards (2) | RF, Large and Small Male and Tongue 400, 600, 900, 1500, & 2500 lb. Standards (2) | Depth of Groove or Female |

| R | S | T | U | W | X | Y | Z | ||||

| 1/2 | 1.38 | 0.72 | 1.38 | 1 | 1.44 | 0.78 | 1.44 | 0.94 | 0.06 | 0.25 | 0.19 |

| 3/4 | 1.69 | 0.94 | 1.69 | 1.31 | 1.75 | 1 | 1.75 | 1.25 | 0.06 | 0.25 | 0.19 |

| 1 | 2 | 1.19 | 1.88 | 1.5 | 2.06 | 1.25 | 1.94 | 1.44 | 0.06 | 0.25 | 0.19 |

| 1 1/4 | 2.5 | 1.5 | 2.25 | 1.88 | 2.56 | 1.56 | 2.31 | 1.81 | 0.06 | 0.25 | 0.19 |

| 1 1/2 | 2.88 | 1.75 | 2.5 | 2.12 | 2.94 | 1.81 | 2.56 | 2.06 | 0.06 | 0.25 | 0.19 |

| 2 | 3.62 | 2.25 | 3.25 | 2.88 | 3.69 | 2.31 | 3.31 | 2.81 | 0.06 | 0.25 | 0.19 |

| 2 1/2 | 4.12 | 2.69 | 3.75 | 3.38 | 4.19 | 2.75 | 3.81 | 3.31 | 0.06 | 0.25 | 0.19 |

| 3 | 5 | 3.31 | 4.62 | 4.25 | 5.06 | 3.38 | 4.69 | 4.19 | 0.06 | 0.25 | 0.19 |

| 3 1/2 | 5.5 | 3.81 | 5.12 | 4.75 | 5.56 | 3.88 | 5.19 | 4.69 | 0.06 | 0.25 | 0.19 |

| 4 | 6.19 | 4.31 | 5.69 | 5.19 | 6.25 | 4.38 | 5.75 | 5.12 | 0.06 | 0.25 | 0.19 |

| 5 | 7.31 | 5.38 | 6.81 | 6.31 | 7.38 | 5.44 | 6.88 | 6.25 | 0.06 | 0.25 | 0.19 |

| 6 | 8.5 | 6.38 | 8 | 7.5 | 8.56 | 6.44 | 8.06 | 7.44 | 0.06 | 0.25 | 0.19 |

| 8 | 10.62 | 8.38 | 10 | 9.38 | 10.69 | 8.44 | 10.06 | 9.31 | 0.06 | 0.25 | 0.19 |

| 10 | 12.75 | 10.5 | 12 | 11.25 | 12.81 | 10.56 | 12.06 | 11.19 | 0.06 | 0.25 | 0.19 |

| 12 | 15 | 12.5 | 14.25 | 13.5 | 15.06 | 12.56 | 14.31 | 13.44 | 0.06 | 0.25 | 0.19 |

| 14 | 16.25 | 13.75 | 15.5 | 14.75 | 16.31 | 13.81 | 15.56 | 14.69 | 0.06 | 0.25 | 0.19 |

| 16 | 18.5 | 15.75 | 17.62 | 16.75 | 18.56 | 15.81 | 17.69 | 16.69 | 0.06 | 0.25 | 0.19 |

| 18 | 21 | 17.75 | 20.12 | 19.25 | 21.06 | 17.81 | 20.19 | 19.19 | 0.06 | 0.25 | 0.19 |

| 20 | 23 | 19.75 | 22 | 21 | 23.06 | 19.81 | 22.06 | 20.94 | 0.06 | 0.25 | 0.19 |

| 24 | 27.25 | 23.75 | 26.25 | 25.25 | 27.31 | 23.81 | 26.31 | 25.19 | 0.06 | 0.25 | 0. |

- Regular facing for 150 and 300 lb. Steel flanged fittings and flange standards is a 1/16 inch raised face included in the minimum flange thickness. A 1/16 inch raised face is also permitted on the 400, 600, 900, 1500, and 2500 Lb. Flange standards, but it must be added to the minimum flange thickness.Regular facing for 400, 600, 900, 1500, and 2500 lb. Flange standards is a ¼ inch raised face not included in minimum flange thickness dimensions.Care should be taken in the use of joints of these dimensions, (they apply particularly on lines where the joint is made on the end of pipe) to insure that pipe used is thick enough to permit sufficient bearing surface to prevent crushing the gasket. Threaded companion flanges are furnished with plain face and are threaded with American Standard Locknut Thread.

Applications:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Where can we find the high quality ASME B16.5 ASTM B564 Nickel Alloy 625 weld neck flange Small Tongue 6 Inch SCH40S CL900.

Applications:

1. Petrochemical industry

2. Pharmaceutical industry

3. Food industry

4. Aviation and aerospace industry

5. Architectural decoration industry

6. Oil and gas industry

Other Features:

1) Chemical and Physical characteristic: durable, corrosion resistant and high-temperature resistant

2) We also produce flange with special specifications according to customers’ requirements;

Where can we find the high quality ASME B16.5 ASTM B564 Nickel Alloy 625 weld neck flange Small Tongue 6 Inch SCH40S CL900.

You can visit this website: tanell.net(Zhejiang Tanell Pipes&Fitting Co., Ltd)

Related products:

More>>

|

|

|

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.