Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Quick Details

| Material: | Hastelloy C276 (UNS N10276) | Technics: | Forged | Type: | 90Deg LR Elbow |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

Packaging & Delivery

| Packaging Details: | Plywood case or fumigation woodern case |

|---|---|

| Delivery Detail: | 2 - 10 days |

Specifications

ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR DN609.6x4MM

1) Size: 24" (DN600)

THK: 4MM

3) Material: Hastelloy C276 (UNS N10276)

China Welded Elbow Manufacturer Tanell supplies ASME B16.9 ASTM B366 Hastelloy C276 90 Degree Welded Elbow LR, DN609.6x4MM.

Chemical Composition of Grade Hastelloy C276 (UNS N10276)

| C | Co | Cr | Fe | Mn | Mo | Ni | P | S | Si | V | W |

| Max | Max | Max | Max | Max | Max | Max | |||||

| 0.01% | 2.5% | 14.5% -16.5% | 4-7% | 1.0% | 15 -17% | BAL | .04% | 0.03% | 0.08% | 0.35% | 3-4.5% |

|

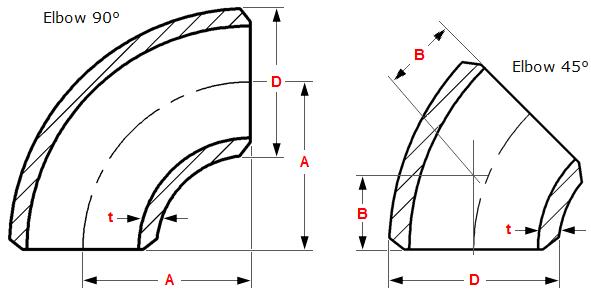

| NPS | O.D. D | 90° Long Rad Center to End A | 45° Long Rad Center to End B | 90° 3D Center to End A | 45° 3D Center to End B |

| 18 | 457 | 686 | 286 | 1372 | 568 |

| 20 | 508 | 762 | 318 | 1524 | 632 |

| 22 | 559 | 838 | 343 | 1676 | 694 |

| 24 | 610 | 914 | 381 | 1829 | 757 |

| 26 | 660 | 991 | 406 | 1981 | 821 |

| 28 | 711 | 1067 | 438 | 2134 | 883 |

| 30 | 762 | 1143 | 470 | 2286 | 946 |

| 32 | 813 | 1219 | 502 | 2438 | 1010 |

| 34 | 864 | 1295 | 533 | 2591 | 1073 |

| 36 | 914 | 1372 | 565 | 2743 | 1135 |

| 38 | 965 | 1448 | 600 | 2896 | 1200 |

| 40 | 1016 | 1524 | 632 | 3048 | 1264 |

| 42 | 1067 | 1600 | 660 | 3200 | 1326 |

| 44 | 1118 | 1676 | 695 | 3353 | 1389 |

| 46 | 1168 | 1753 | 727 | 3505 | 1453 |

| 48 | 1219 | 1829 | 759 | 3658 | 1516 |

Dimensions are in millimeters unless otherwise indicated. Wall thickness (t) must be specified by customer.

DIMENSIONAL TOLERANCES OF BUTT WELD ELBOWS - 45° AND 90° - LR AND 3D - ASME B16.9

| Nominal Pipe Size | 1/2 to 2.1/2 | 3 to 3.1/2 | 4 | 5 to 8 |

| Outside Diameter at Bevel (D) | + 1.6 - 0.8 | 1.6 | 1.6 | + 2.4 - 1.6 |

| Inside Diameter at End | 0.8 | 1.6 | 1.6 | 1.6 |

| Center to End LR (A/B) | 2 | 2 | 2 | 2 |

| Center to End 3D (A/B) | 3 | 3 | 3 | 3 |

| Nominal Pipe Size | 10 to 18 | 20 to 24 | 26 to 30 | 32 to 48 |

| Outside Diameter at Bevel (D) | + 4 - 3.2 | + 6.4 - 4.8 | + 6.4 - 4.8 | + 6.4 - 4.8 |

| Inside Diameter at End | 3.2 | 4.8 | + 6.4 - 4.8 | + 6.4 - 4.8 |

| Center to End LR (A/B) | 2 | 2 | 3 | 5 |

| Center to End 3D (A/B) | 3 | 3 | 6 | 6 |

| Wall Thickness (t) | Not less than 87.5% of Nominal Wall Thickness | |||

Dimensional tolerances are in millimeters unless otherwise indicated and are equal ± except as noted.

Note:

MSS SP-43 only covers stainless steel buttweld fittings made for use with Schedule 5S and 10S pipe and Stub Ends suitable for use with Schedule 40S pipe, as defined in ASME B36.19. The dimensions and dimensional tolerances defined in MSS SP-43 are substantially the same as those in ASME B16.9 specifications from NPS 1/2 - NPS 24. Except with regard to the outside diameter at the bevel.

In what forms is Hastelloy C276 Available?

Bar

Sheet

Plate

Pipe & Tube (welded and seamless)

Pipe Fittings

Welding Wire

Corrosion Resistant Hastelloy C276

Considered one of the most versatile corrosion resistant alloys available, Hastelloy C-276 exhibits excellent resistance in a wide variety of chemical process environments including those with ferric and cupric chlorides, hot contaminated organic and inorganic media, chlorine, formic and acetic acids, acetic anhydride, seawater, brine and hypochlorite and chlorine dioxide solutions. In addition, alloy C-276 resists formation of grain boundary precipitates in the weld heat affected zone making it useful for most chemical processes in the as-welded condition. This alloy has excellent resistance to pitting and stress corrosion cracking.

What are the characteristics of Hastelloy C276?

Excellent corrosion resistance in reducing environments

Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

High nickel and molybdenum contents providing good corrosion resistance in reducing environments

Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints

Resistance to localized corrosion such as pitting and stress-corrosion cracking

One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide

In what applications is Hastelloy C-276 used?

Pollution control stack liners, ducts, dampers, scrubbers, stack-gas reheaters, fans and fan housings

Flue gas desulfurization systems

Chemical processing components like heat exchangers, reaction vessels, evaporators, and transfer piping

Sour gas wells

Pulp and paper production

Waste treatment

Pharmaceutical and food processing equipment

Fabrication with Hastelloy C-276

Hastelloy C-276 alloy can be forged, hot-upset and impact extruded. Although the alloy tends to work-harden, you can have it successfully spun, deep-drawn, press formed or punched. All of the common methods of welding can be used, although the oxyacetylene and submerged arc processes are not recommended when the fabricated item is for use in corrosion service.

Hastelloy C-276 Welding Material

Alloy C276 welding products are used as matching composition filler material for welding C276 alloy wrought and cast products, for dissimilar welding applications including other nickel-chromium-molybdenum alloys and stainless steels, and for weld overlay or cladding of steels.

If any inquiry , please feel free to contact us tan@tanell.com

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.