Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

ASME B16.9 ASTM B366 Alloy 600 90 Degree LR Elbow 2-1/2 Inch SCH10S

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Quick Details

| Material: | Inconel 600 (UNS N06600/Alloy 600) | Technics: | Forged | Type: | 90Deg LR Elbow |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

Packaging & Delivery

| Packaging Details: | Plywood case or fumigation woodern case |

|---|---|

| Delivery Detail: | 2 - 10 days |

Specifications

ASME B16.9 ASTM B366 Alloy 400 90 Degree LR Elbow 1-1/2 Inch SCH10S

1) Size: 2-1/2 Inch (DN65)

THK: Sch10S

3) Material: Inconel 600 (UNS N06600/Alloy 600)

Inconel 600 is a nickel-chromium alloy used for applications that require corrosion and high temperature resistance. This nickel alloy was designed for service temperatures from cryogenic to elevated temperatures in the range of 2000° F. It is non-magnetic, has excellent mechanical properties, and presents the desirable combination of high strength and good weldability under a wide range of temperatures. The high nickel content in Inconel 600 enables it to retain considerable resistance under reducing conditions, makes it resistant to corrosion by a number of organic and inorganic compounds, gives it excellent resistance to chloride-ion stress-corrosion cracking and also provides excellent resistance to alkaline solutions. Typical applications of this nickel alloy include the chemical, pulp and paper, aerospace, nuclear engineering and heat treating industries.

Alloy 600 can be both hot formed and cold formed using typical processes. Hot working should be performed between 1600°F and 2250°F avoiding any work between1200-1600°F because the ductility decreases in this temperature range. Welding Alloy 600 can be achieved via shielded metal-arc welding, TIG, and MIG.

China SMLS Elbow Manufacturer Tanell supplies ASME B16.9 ASTM B366 Alloy 600 90 Degree LR Elbow, 2-1/2 Inch, SCH10S.

| Ni + Co | Cr | Fe | C | Mn | S | Si | Cu |

| 72.0 min | 14.0-17.0 | 6.0-10.0 | .15 max | 1.00 max | .015 max | .50 max | .50 max |

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting |

| B167 | B517 | B163 | B516 | B168 | B166 | B564 | B366 |

Typical room temperature Tensile Properties of Annealed Material

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

| Rod & Bar | Cold-Drawn | 80-100 | 25-50 | 35-55 | 65-85 |

| Rod & Bar | Hot-Finished | 80-100 | 30-50 | 35-55 | 65-85 |

| Tube & Pipe | Hot-Finished | 75-100 | 25-50 | 35*55 | - |

| Tube & Pipe | Cold-Drawn | 80-100 | 25-50 | 35-55 | 88 Max |

| Plate | Hot-Rolled | 80-105 | 30-50 | 35-55 | 65-85 |

| Sheet | Cold-Drawn | 80-100 | 30-45 | 35-55 | 88 Max |

|

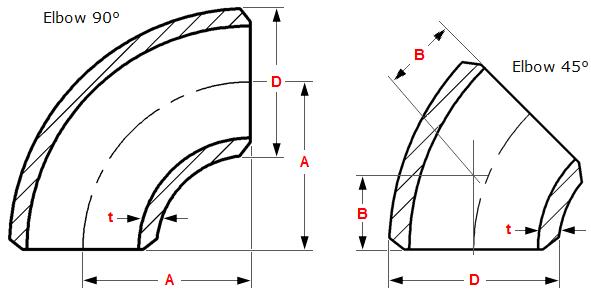

| NPS | O.D. D | 90° Long Rad Center to End A | 45° Long Rad Center to End B | 90° 3D Center to End A | 45° 3D Center to End B |

| 1/2 | 21.3 | 38 | 16 | … | … |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

In what forms is Monel 600 Available?

Sheet

Plate

Bar

Pipe & Tube (welded & seamless)

Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

Wire

What are the characteristics of Monel 600?

Resistant to a wide range of corrosive media.

Virtually immune to chlorine ion stress corrosion cracking

Non-magnetic

Excellent mechanical properties

High strength and good weldability under a wide range of temperatures

In what applications is Monel 400 used?

Chemical industry

Aerospace

Heat treating industry

Pulp and paper industry

Food processing

Nuclear Engineering

Gas turbine components

If any inquiry, please feel free to contact by email tan@tanell.com

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.