Products

Credibility ,the lifeblood of enterprise!

- Fittings

- Butt Welding Fittings

- Forged Fittings

- 180 Degree Elbows

- 90 Degree Elbows

- 60 Degree Elbows

- 45 Degree Elbows

- 30 Degree Elbows

- Equal Tee

- Reducing Tee

- Concentric Reducer

- Eccentric Reducer

- Lap Joint Stub End

- Outlets

- Cap

- Bend

- Cross

- Coupling

- Stainless Steel Lateral Tee

- Bellows Expansion Joints

- Flexible Metal Hose

- Non-Standard/Custom Fittings

- Bleed & Flushing Rings

- Types of Flanges

- Anchor Flanges

- Blind Flanges

- Expander Flanges

- High Hub Flanges

- Lap Joint Flanges

- Long Weld Neck Flanges

- Nipoflanges

- Orifice Flanges

- Plate Flanges

- Ring Type Joint Flanges

- Reducing Flanges

- Slip On Flanges

- Socket Weld Flanges

- Spectacle Blind Flanges

- Square Flanges

- Spades & Ring Spacers

- Threaded Flanges

- Welding Neck Flanges

SME B16.9 ASTM B366 Alloy 400 90 Degree LR Elbow 1-1/2 Inch SCH10S

- FOB Price USD 1 - 1,900/Piece

- Port Ningbo or Shanghai Port

- MOQ 1 Piece

- Supply Ability 1000 Pieces Per Day

- Payment Terms L/C,T/T,Western Union,MoneyGram

- Packaging Seaworthy plywood cases or pallets

- Delivery 2 - 10 days

Quick Details

| Material: | Monel 400 (UNS N04400/Alloy 400) | Technics: | Forged | Type: | 90Deg LR Elbow |

| Place of Origin: | Zhejiang, China (Mainland) | Head Code: | Round | Brand Name: | Tanell |

| Connection: | Welding | Shape: | Equal |

Packaging & Delivery

| Packaging Details: | Plywood case or fumigation woodern case |

|---|---|

| Delivery Detail: | 2 - 10 days |

Specifications

ASME B16.9 ASTM B366 Alloy 400 90 Degree LR Elbow 1-1/2 Inch SCH10S

1) Size: 1-1/2 Inch (DN40)

THK: Sch10S

3) Material: Monel 400 (UNS N04400/Alloy 400)

Monel 400 is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength.

China SMLS Elbow Manufacturer Tanell supplies ASME B16.9 ASTM B366 Alloy 400 90 Degree LR Elbow, 1-1/2 Inch, SCH10S.

Monel 400 (UNS N04400/Alloy 400) Chemical Composition, %

| C | Mn | S | Si | Ni | Cu | Fe |

| .30 max | 2.00 max | .024 max | .50 max | 63.0 min | 28.0-34.0 | 2.50 max |

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Forging | Fitting | Wire |

| B165 | B725 | B163 | B127 | B164 | B564 | B366 |

| Product Form | Condition | Tensile (ksi) | .2% Yield (ksi) | Elongation (%) | Hardness (HRB) |

| Rod & Bar | Annealed | 75-90 | 25-50 | 60-35 | 60-80 |

| Rod & Bar | Cold-Drawn Stress Relieved | 84-120 | 55-100 | 40-22 | 85-20 HRC |

| Plate | Annealed | 70-85 | 28-50 | 50-35 | 60-76 |

| Sheet | Annealed | 70-85 | 30-45 | 45-35 | 65-80 |

| Tube & Pipe Seamless | Annealed | 70-85 | 25-45 | 50-35 | 75 max * |

|

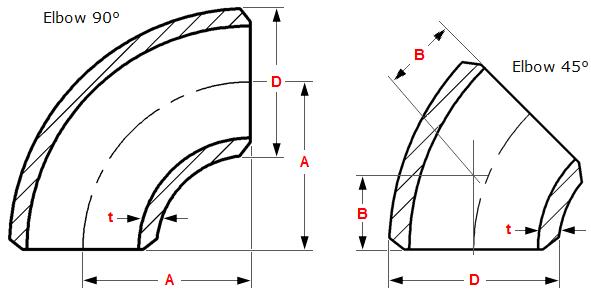

| NPS | O.D. D | 90° Long Rad Center to End A | 45° Long Rad Center to End B | 90° 3D Center to End A | 45° 3D Center to End B |

| 1/2 | 21.3 | 38 | 16 | … | … |

| 3/4 | 26.7 | 38 | 19 | 57 | 24 |

| 1 | 33.4 | 38 | 22 | 76 | 31 |

| 1¼ | 42.2 | 48 | 25 | 95 | 39 |

| 1½ | 48.3 | 57 | 29 | 114 | 47 |

| 2 | 60.3 | 76 | 35 | 152 | 63 |

| 2½ | 73 | 95 | 44 | 190 | 79 |

| 3 | 88.9 | 114 | 51 | 229 | 95 |

| 3½ | 101.6 | 133 | 57 | 267 | 111 |

| 4 | 114.3 | 152 | 64 | 305 | 127 |

| 5 | 141.3 | 190 | 79 | 381 | 157 |

| 6 | 168.3 | 229 | 95 | 457 | 189 |

| 8 | 219.1 | 305 | 127 | 610 | 252 |

| 10 | 273 | 381 | 159 | 762 | 316 |

| 12 | 323.8 | 457 | 190 | 914 | 378 |

| 14 | 355.6 | 533 | 222 | 1067 | 441 |

| 16 | 406.4 | 610 | 254 | 1219 | 505 |

In what forms is Monel 400 Available?

Sheet

Plate

Bar

Pipe & Tube (welded & seamless)

Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

Wire

What are the characteristics of Monel 400?

Resistant to seawater and steam at high temperatures

Excellent resistance to rapidly flowing brackish water or seawater

Excellent resistance to stress corrosion cracking in most freshwaters

Particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated

Offers some resistance to hydrochloric and sulfuric acids at modest temperatures and concentrations, but is seldom the material of choice for these acids

Excellent resistance to neutral and alkaline salt

Resistance to chloride induced stress corrosion cracking

Good mechanical properties from sub-zero temperatures up to 1020° F

High resistance to alkalis

In what applications is Monel 400 used?

Marine engineering

Chemical and hydrocarbon processing equipment

Gasoline and freshwater tanks

Crude petroleum stills

De-aerating heaters

Boiler feed water heaters and other heat exchangers

Valves, pumps, shafts, fittings, and fasteners

Industrial heat exchangers

Chlorinated solvents

Crude oil distillation towers

If any inquiry, please feel free to contact by email tan@tanell.com

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.