Quick Details

Material: Hastelloy C276 (UNS N10276)

Technics: Cold forming

Type: Welded Stub End

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Tanell

Connection: Welding

Head Code: Round

Size: 24" (DN600)

Products

Credibility ,

Material: Hastelloy C276 (UNS N10276)

Technics: Cold forming

Type: Welded Stub End

Place of Origin: Zhejiang, China (Mainland)

Brand Name: Tanell

Connection: Welding

Head Code: Round

Size: 24" (DN600)

| Packaging Details: | fumigation free plywood cases or as per customers' requests |

|---|---|

| Delivery Detail: | Delivery after receiving deposit |

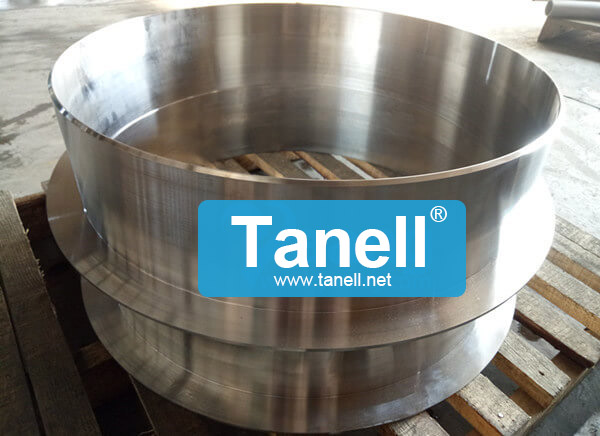

ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM

Size: 24" (DN600)

Thk: 4MM

Material: Hastelloy C276 (UNS N10276)

China STUB END Manufacturer Tanell offers ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End, DN609.6x4MM.

Chemical Composition of Grade Hastelloy C276 (UNS N10276)

| C | Co | Cr | Fe | Mn | Mo | Ni | P | S | Si | V | W |

| Max | Max | Max | Max | Max | Max | Max | |||||

| 0.01% | 2.5% | 14.5% -16.5% | 4-7% | 1.0% | 15 -17% | BAL | .04% | 0.03% | 0.08% | 0.35% | 3-4.5% |

Type | Hastelloy C276 Welded Stub End |

Standard | ASME B16.9, MSS SP-43, HG205099, HG20621, GB/T12459-2005, GB/T13401, SH3408-96,etc. |

Size | 1/2"-48"(DN15-DN600) |

Wall thickness | SCH5S-SCH40S |

Type | Type A, Type B,Type C |

Surface treatment | Lathe finish&Abrasive blasting |

Stainless steel | 304, 304L,304H, 316, 316L,309S,310S, 321,321H,347H,316Ti |

Duplex steel | 2205, etc |

Super duplex steel | 2507, etc |

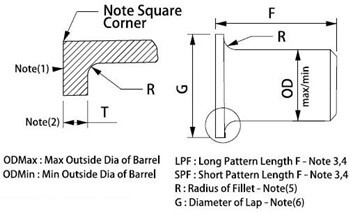

Dimensions of ASME B16.9 Lap Joint Stub End

| NPS | ODMax | ODMin | LPF | SPF | R | G |

| 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1 | 35.0 | 32.6 | 102 | 51 | 3 | 51 |

| 1-1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 11/2 | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2-1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3-1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 140 |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 12 | 328.0 | 323.1 | 254 | 152 | 13 | 381 |

| NPS | ODMax | ODMin | LPF | SPF | R | G |

| 14 | 359.9 | 354.8 | 305 | 152 | 13 | 413 |

| 16 | 411.0 | 405.6 | 305 | 152 | 13 | 470 |

| 18 | 462.0 | 456.0 | 305 | 152 | 13 | 533 |

| 20 | 514.0 | 507.0 | 305 | 152 | 13 | 584 |

| 22 | 565.0 | 558.0 | 305 | 152 | 13 | 641 |

| 24 | 616.0 | 609.0 | 305 | 152 | 13 | 692 |

(a) All dimensions are in millimeters.

(b) See Table 13 for tolerances.

(c) Service conditions and joint construction often dictate stub end length requirements. Therefore, the purchaser must specify long or short pattern fitting when ordering.

(1) Gasket face finish shall be in accordance with ASME B16.5 for raised face flanges.

(2) The lap thickness T shall not be less than nominal pipe wall thickness. See Table 13 for maximum tolerance.

(3) When short pattern stub ends are used with larger flanges in Classes 300 and 600, with most sizes in Classes 900 and higher, and

when long pattern stub ends are used with larger flanges in Classes 1500 and 2500, it may be necessary to increase the length of the

stub ends in order to avoid covering the weld with the flange. Such increases in length shall be a matter of agreement between the

manufacturer and purchaser.

(4) When special facings such as tongue and groove, male and female, etc., are employed, additional lap thickness must be provided and

such additional thickness shall be in addition to (not included in) the basic length F.

(5) These dimensions conform to the radius established for lap joint flanges in ASME B16.5.

(6) This dimension conforms to standard machined facings shown in ASME B16.5. The back face of the lap shall be machined to conform

to the surface on which it seats. Where ring joint facings are to be applied, use dimension K as given in ASME B16.5.

Hastelloy C276 Welded Stub End

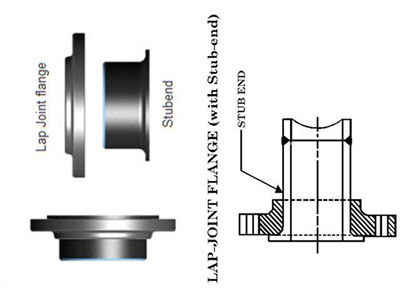

What are they?

Hastelloy C276 Welded Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired.They are also called Lap Joints and Vanstone Flared Laps.

How do they work?

A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Why?

Since Stub Ends are made from material compatible with the designed piping system, back up flanges do not have to be made from the same material. The flange can be made from less expensive material because it never comes in contact with the process fluid.

Hastelloy C276 Welded Stub Ends' TypesWhere can we find the high quality ASME B16.9 ASTM B366 Hastelloy C276 Welded Stub End DN609.6x4MM.

Sheet

Plate

Bar

Pipe & Tube (welded & seamless)

Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

Wire

Resistant to a wide range of corrosive media.

Virtually immune to chlorine ion stress corrosion cracking

Non-magnetic

Excellent mechanical properties

High strength and good weldability under a wide range of temperatures

You can visit this website: tanell.net(Zhejiang Tanell Pipes&Fitting Co., Ltd)

Tel:+86-577-85982258 / Email:tan@tanell.com

Address:NO.568-D Three Street Three Road,Binhai Wenzhou Zhejiang

COPYRIGHT©2024 tanell.net Zhejiang Tanell Pipes&Fitting Co., Ltd

Tanell is an company that operates in the supplying market for Oil and Gas plant, Chemical industry, Energy and Water since 1981.